Soft robot muscles origami skeleton mit harvard presents a fascinating new frontier in robotics. Imagine robots that are as flexible and adaptable as living organisms, using the principles of origami to create intricate and responsive structures. This innovative approach promises a revolution in how we design and utilize robots in various applications.

This exploration delves into the specifics of soft robot muscles, highlighting their unique properties and the materials used in their fabrication. We’ll also examine the origami-inspired skeleton design, exploring how this ancient art form can be translated into sophisticated robotic structures. The research at Harvard University, focusing on integrating these soft muscles and skeletons, will be analyzed, along with potential applications and the future of this exciting field.

Introduction to Soft Robot Muscles

Soft robot muscles, a crucial component in the development of adaptable and versatile robots, are inspired by the natural world’s soft tissues. These artificial muscles mimic the dynamic contractions and relaxations of biological muscles, enabling robots to perform complex movements with a level of dexterity and adaptability that traditional rigid robots cannot match. Their flexibility and resilience open up new avenues in robotics, from delicate medical procedures to intricate assembly tasks.These artificial muscles, unlike their rigid counterparts, offer a remarkable degree of adaptability and compliance.

This allows them to conform to complex shapes and environments, making them ideal for navigating intricate spaces and interacting with objects in a more natural and intuitive manner. The design of soft robot muscles relies heavily on materials that can be deformed in a controlled manner, enabling the creation of intricate and dynamic movement patterns.

Materials and Fabrication Methods

The materials used in soft robot muscles are carefully chosen for their mechanical properties and ability to undergo controlled deformation. Common materials include shape memory alloys, dielectric elastomers, and pneumatic actuators. Each material type has its unique characteristics that influence the performance and design of the muscles. For example, shape memory alloys exhibit a remarkable ability to return to their original shape after deformation, while dielectric elastomers can generate large strains under electrical stimulation.

Examples of Soft Robot Muscles

Various types of soft robot muscles have been developed, each with its unique properties and applications. For instance, shape memory alloy (SMA) muscles utilize the shape memory effect of certain metals to contract and expand, while dielectric elastomer (DE) actuators leverage the piezoelectric effect to deform in response to electrical fields. These muscles can be designed to mimic a range of biological functions, from muscle contractions to the movement of biological tissues.

Furthermore, pneumatic actuators, which utilize compressed air, are also commonly employed in soft robotics due to their ease of control and large deformation capabilities.

Comparison of Soft Robot Muscle Types, Soft robot muscles origami skeleton mit harvard

| Muscle Type | Material | Mechanism | Advantages | Disadvantages |

|---|---|---|---|---|

| Shape Memory Alloys (SMAs) | Nickel-Titanium alloys (Nitinol) | Phase transformation | High force generation, good fatigue resistance | Complex fabrication, limited strain |

| Dielectric Elastomers (DEs) | Polymers with embedded electrodes | Electrical field-induced deformation | Large strain, fast response | Low force generation, susceptible to breakdown |

| Pneumatic Actuators | Flexible tubes, chambers | Pressure-induced deformation | High force generation, simple control | Limited speed, bulky design |

This table highlights the key characteristics of different soft robot muscle types. The choice of material and fabrication method depends on the specific application requirements, such as the desired force, speed, and range of motion. For example, if a high force is needed, pneumatic actuators are more suitable than dielectric elastomers. If a fast response time is crucial, dielectric elastomers might be a better choice.

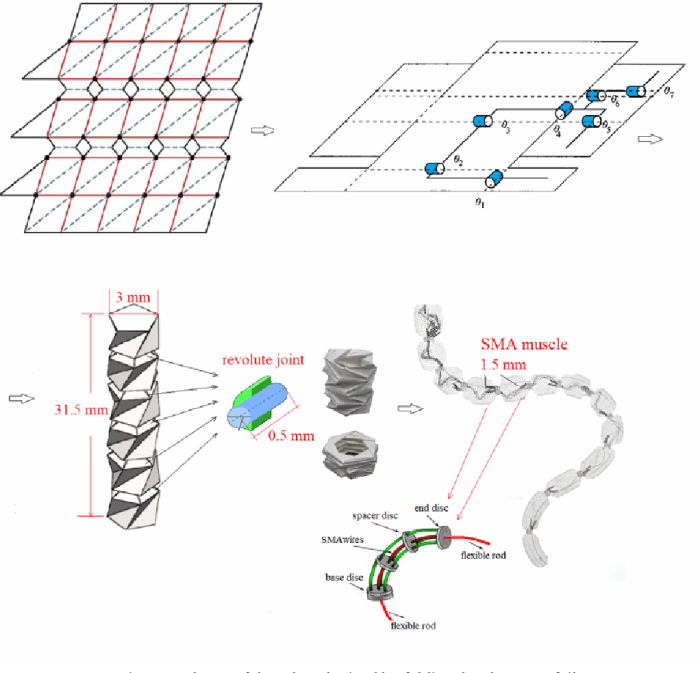

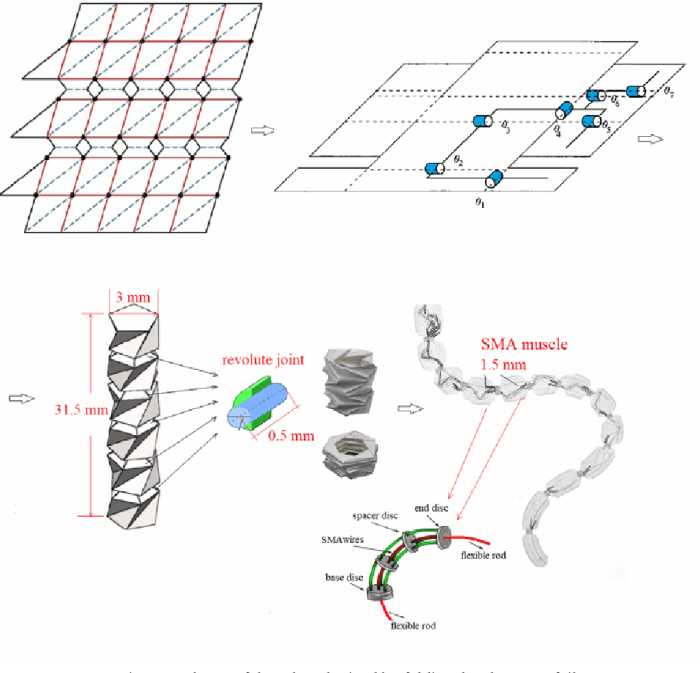

Origami-Inspired Skeleton Design

Origami, the ancient art of paper folding, transcends its aesthetic appeal to reveal powerful principles of structural engineering. Its intricate folding patterns can be translated into robust and adaptable designs for soft robots, offering a novel approach to creating flexible and responsive robotic systems. This exploration delves into the application of origami principles to create intricate and functional skeletons for soft robots, emphasizing the unique advantages of this method.Origami’s elegance lies in its ability to transform a flat sheet of material into complex three-dimensional structures.

This inherent ability to create intricate shapes from simple folds provides a valuable framework for designing soft robot skeletons. The method allows for the precise control of material deformation and stress distribution, which is crucial for creating robots that can adapt to diverse environments and tasks.

Folding Patterns for Soft Robot Skeletons

Origami folding patterns offer a diverse range of structural possibilities. The fundamental folds, such as valley folds and mountain folds, can be combined to create intricate frameworks that provide support and flexibility. For example, a series of carefully arranged valley folds can create a strong, yet deformable, structure, mimicking the skeletal support found in living organisms.

Materials for Origami-Inspired Skeletons

The selection of materials for origami-inspired soft robot skeletons is crucial. The material should possess the desired level of flexibility, strength, and responsiveness. Common materials include elastomers, hydrogels, and composites. Elastomers provide a balance of elasticity and durability, making them suitable for applications requiring deformation and recovery. Hydrogels, which swell and shrink in response to changes in their surrounding environment, are ideal for actuators and sensors.

Harvard’s innovative soft robot muscles, inspired by origami skeletons, are pretty cool. While I’m fascinated by their potential, I also need to check out the Sony Xperia 5 II price release date features here. Ultimately, I’m excited to see how these bio-inspired designs continue to push the boundaries of robotics, especially in mimicking natural movements.

Hybrid materials, combining the strengths of multiple components, offer greater design freedom and can potentially lead to more sophisticated and functional robots.

Conceptual Design: A Multi-Layered Origami Skeleton

This design concept uses multiple layers of thin, flexible elastomer sheets to form a complex, layered structure. The layers are interconnected using precisely engineered origami folding patterns. The initial design utilizes valley folds and pleats to create a complex lattice structure, allowing for precise control of the robot’s shape and movement. This layered approach provides a significant advantage, offering greater stiffness in certain directions while maintaining flexibility in others.

The material properties of the elastomer dictate the specific folding patterns, allowing for controlled deformation and actuation. This intricate framework can be further enhanced with embedded actuators, providing additional degrees of freedom and enabling more complex motions.

Table of Origami-Inspired Designs and Applications

| Design | Folding Pattern | Materials | Potential Applications |

|---|---|---|---|

| Modular Arm | Interlocking modules | Elastomer | Manipulating objects, grasping tools, assisting in tasks |

| Expandable Cage | Accordion-like folds | Hydrogels | Environmental sensing, adaptive camouflage, soft gripping |

| Articulated Leg | Hierarchical folding | Composite elastomer | Locomotion, legged robots, climbing |

| Flexible Antenna | Curved folds | Elastomer | Sensing vibrations, detecting changes in pressure, monitoring environments |

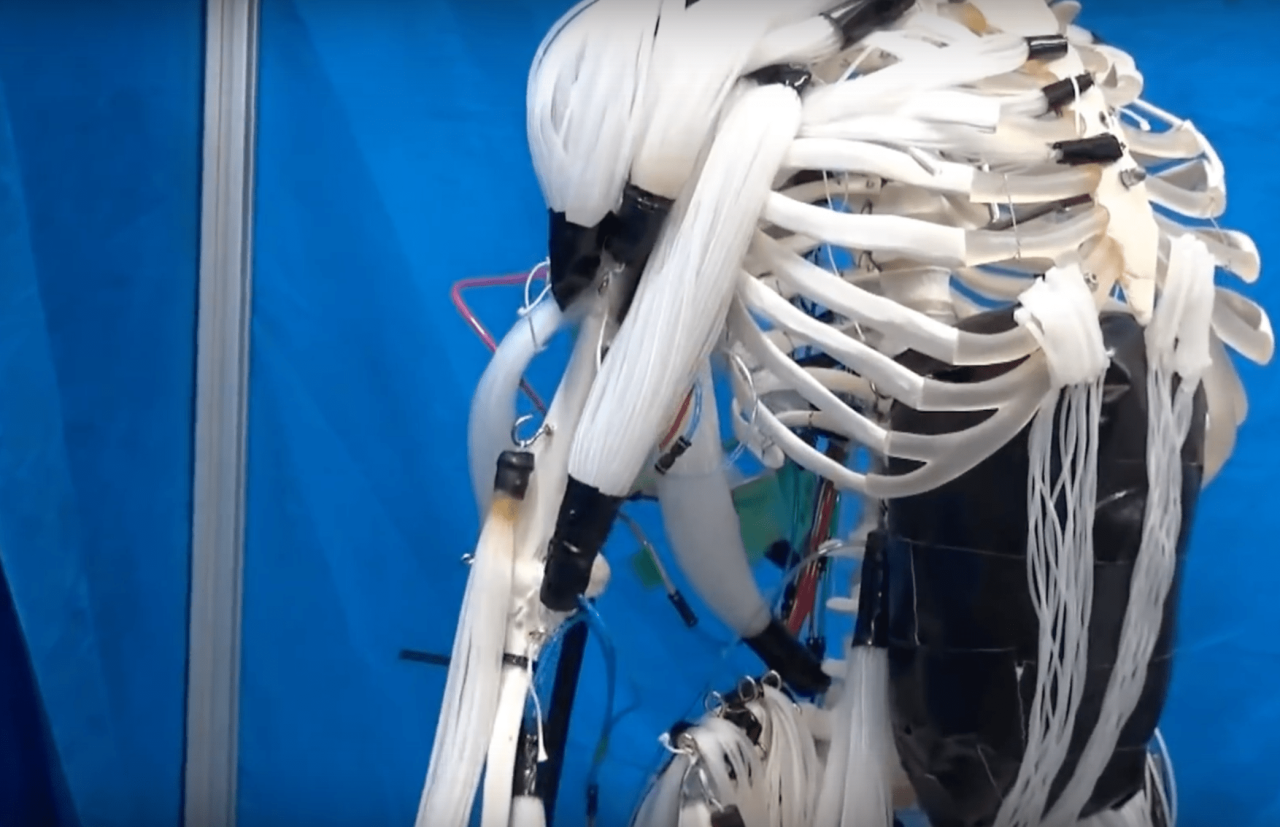

Harvard’s Research on Soft Robotics

Harvard University has been a prominent player in the burgeoning field of soft robotics, pushing the boundaries of what’s possible with bio-inspired designs and innovative materials. Their research leverages the inherent advantages of soft actuators and adaptable structures, paving the way for robots capable of navigating complex environments and interacting with humans in novel ways. This exploration delves into specific projects, key findings, and the challenges tackled by Harvard researchers in this domain.Harvard’s research on soft robotics has focused on several key areas, including the development of advanced soft actuators and the integration of origami-inspired structures.

This research has produced significant advancements in the field, offering solutions to challenges that traditional robotics often faces. The use of soft materials allows for greater flexibility and adaptability, making these robots suitable for diverse applications.

Specific Research Projects

Harvard researchers have explored a variety of soft robot projects. One prominent example involves the design and fabrication of soft robot muscles mimicking the contraction and relaxation of biological muscles. These muscles are often made from shape-memory polymers, electroactive polymers, or other responsive materials. The development of these soft actuators has focused on optimizing their performance, including their force generation capabilities and response times.

Furthermore, integration with origami-inspired skeletons allows for complex and intricate movements, often with greater degrees of freedom compared to rigid robots. This approach enhances the versatility and adaptability of the robot.

Key Findings and Innovations

Harvard’s research has yielded several significant findings and innovations. One key innovation is the development of bio-inspired soft actuators capable of generating controlled forces and movements. Researchers have explored different actuation mechanisms and material combinations to achieve enhanced performance. Another significant innovation is the development of origami-inspired structures for soft robots. These structures allow for greater flexibility, adaptability, and the ability to conform to complex environments.

Challenges Addressed

The research has tackled several critical challenges in soft robotics. One significant challenge is the development of soft actuators that can generate sufficient force and maintain their performance over time. Researchers have addressed this by investigating different material properties and actuation mechanisms. Another key challenge is integrating soft actuators with complex structures to achieve intricate movements. The origami-inspired approach offers solutions to this challenge by allowing for greater degrees of freedom and structural adaptability.

Significance of Harvard’s Contributions

Harvard’s contributions to soft robotics are significant. By exploring bio-inspired designs and innovative materials, the research has advanced the capabilities of soft robots, making them suitable for a broader range of applications. The development of soft actuators and origami-inspired skeletons offers solutions to challenges in traditional robotics. This advancement opens doors for innovative applications in various fields, from medical interventions to environmental monitoring.

Integration of Soft Muscles and Origami Skeletons

Bringing soft robot muscles and origami-inspired skeletons together presents a fascinating challenge and exciting opportunity. The inherent flexibility and responsiveness of soft actuators combined with the intricate, load-bearing capabilities of origami structures promise highly adaptable and potentially biomimetic robots. The key lies in seamlessly integrating these two distinct components, enabling the origami framework to effectively guide and direct the muscle contractions for controlled motion.The integration process hinges on a precise understanding of how the soft muscles’ actuation translates into the desired movements within the origami skeleton.

This involves careful consideration of the materials used for both components, ensuring compatibility and minimizing potential friction or damage. Methods for anchoring and connecting the muscles to the skeleton are crucial, as is the selection of appropriate actuation mechanisms to drive the muscles within the constrained origami structure.

Mechanisms for Integrating Soft Muscles

The integration of soft muscles with origami skeletons necessitates careful consideration of the attachment points and the actuation methods. Direct attachment methods, such as adhesives or sutures, offer a straightforward approach. However, these techniques may not always allow for the required flexibility or range of motion. Alternatively, the use of compliant joints or hinges within the origami structure can accommodate the soft muscles’ deformation and enable more complex movements.

These hinges need to be carefully designed to balance flexibility and structural integrity.

Actuation Methods within the Origami Structure

Several actuation methods can be employed to drive the soft muscles within the origami structure. Pneumatic actuation, utilizing pressurized air to expand or contract the muscles, offers a straightforward and relatively simple approach. Electroactive polymers (EAPs) provide another possibility, offering precise control over the muscles’ expansion and contraction using electrical signals. The choice of actuation method depends on factors such as the desired speed, force, and precision of the robot’s movements.

The origami structure itself can play a crucial role in optimizing the actuation by concentrating forces or directing the deformation of the muscles.

Challenges in Achieving Seamless Integration

While the integration of soft muscles and origami skeletons offers significant potential, several challenges need to be addressed. One key challenge lies in achieving a robust and reliable connection between the two components. This necessitates the development of materials and interfaces that can withstand the forces generated by the muscles while maintaining the structural integrity of the origami skeleton.

Another challenge involves the complexity of controlling multiple muscles within a complex origami structure to achieve intricate and coordinated movements. The delicate balance between the flexibility of the soft muscles and the rigidity of the origami structure also requires careful consideration.

Table of Integration Methods

| Integration Method | Advantages | Disadvantages |

|---|---|---|

| Direct Attachment (e.g., adhesives, sutures) | Simplicity, low cost | Limited flexibility, potential for damage, difficulty in controlling complex movements |

| Compliant Joints | Increased flexibility, accommodates muscle deformation | Complexity in design and fabrication, potential for reduced actuation efficiency |

| Pneumatic Actuation | Simple, relatively low cost, high force output | Potential for leakage, limited precision |

| Electroactive Polymers (EAPs) | High precision, low power consumption | Limited force output, complexity in fabrication |

Potential Applications and Advantages

Soft robots with origami-inspired skeletons and soft muscles represent a paradigm shift in robotics. Their flexibility, adaptability, and potential for intricate movements open doors to applications previously unimaginable with traditional rigid robots. This new generation of robots promises to tackle complex tasks in diverse environments, from minimally invasive surgery to delicate material handling.

Potential Applications

This innovative approach to robotics has a broad range of potential applications, spanning various fields. The unique properties of soft actuators and flexible skeletons allow for interaction with complex and unpredictable environments.

- Medical Applications: Minimally invasive surgery, drug delivery systems, and rehabilitation robotics are prime examples. Imagine a robot capable of navigating delicate blood vessels or delivering targeted medication with unparalleled precision. These robots could revolutionize surgical procedures, reducing invasiveness and improving patient outcomes.

- Material Handling and Manufacturing: Soft robots can perform tasks requiring dexterity and adaptability, such as assembling intricate components in manufacturing or handling delicate materials in laboratories. Their ability to conform to irregular surfaces could significantly improve efficiency and safety in manufacturing processes.

- Environmental Monitoring and Remediation: Soft robots can access hard-to-reach or hazardous environments, such as underwater trenches or contaminated areas. Their flexible bodies allow them to navigate complex terrains and perform tasks such as collecting samples or cleaning up spills.

- Search and Rescue: These robots’ adaptability and ability to maneuver in confined spaces make them suitable for search and rescue operations. Their soft bodies would allow them to navigate through rubble and debris, increasing the chances of finding survivors.

- Human-Robot Interaction: Soft robots can be designed for human-robot collaboration, allowing for gentler and safer interaction in environments where humans and robots need to work together.

Advantages over Traditional Robots

Traditional robotic systems often struggle with tasks requiring flexibility, dexterity, and adaptability. Soft robots with origami skeletons offer several advantages in these situations.

- Increased Dexterity and Adaptability: The flexible nature of soft robots allows them to conform to irregular surfaces and navigate complex environments. This contrasts sharply with rigid robots that often require specific and predictable environments.

- Enhanced Safety: Soft robots are generally safer for human interaction compared to rigid robots, which can pose a risk of injury in certain applications. The compliant nature of these robots prevents potential harm in close proximity to people.

- Improved Biocompatibility: Soft robots designed with biocompatible materials can be used in medical applications, minimizing the risk of rejection or adverse reactions in the human body.

- Reduced Cost: The relatively simple design and fabrication process of some soft robots can potentially lead to lower manufacturing costs compared to complex rigid robots.

- Improved Energy Efficiency: Their reduced mass and streamlined designs can contribute to energy efficiency, especially in applications requiring long-duration operation.

Specific Impact Areas

The impact of this technology spans across several industries, offering unique solutions to challenging problems. These robots can revolutionize healthcare, manufacturing, and environmental science.

| Application | Potential Benefits | Potential Drawbacks |

|---|---|---|

| Medical Surgery | Minimally invasive procedures, increased precision, reduced recovery time | Complexity in control systems, potential for complications |

| Material Handling | Enhanced dexterity, adaptability to complex shapes, improved safety | Lower payload capacity compared to rigid robots, limited strength |

| Environmental Monitoring | Access to hard-to-reach areas, enhanced data collection | Durability in harsh environments, power requirements |

| Search and Rescue | Navigation in challenging terrains, improved survival rate | Limited operating time, robustness in extreme conditions |

| Human-Robot Interaction | Gentle interaction, improved collaboration | Potential for slower reaction times, limitations in strength |

Future Directions and Research: Soft Robot Muscles Origami Skeleton Mit Harvard

The burgeoning field of soft robotics, particularly the integration of soft actuators and origami-inspired structures, presents a wealth of untapped potential. Pushing the boundaries of this technology promises advancements in diverse applications, from minimally invasive surgery to delicate manipulation tasks in harsh environments. This exploration delves into the promising future directions, highlighting potential breakthroughs, and identifying key areas needing further development.The combination of soft actuators and origami skeletons offers unique advantages for intricate and adaptable robots.

Harvard’s MIT soft robot muscles with their origami-like skeleton are pretty cool, right? Imagine the possibilities for new kinds of robotics! Interestingly, the recent news about Elon Musk and Donald Trump’s Twitter ban lifting elon musk donald trump twitter ban lift might have implications for future developments in this field. Still, the potential for these soft robot muscles and skeletons at MIT is quite exciting, and the innovative design is sure to spark more interest in the future.

Further research should focus on optimizing these systems for specific tasks and environments. This includes improving the materials’ properties, refining the design principles, and developing sophisticated control algorithms. The potential for creating robots with enhanced dexterity, adaptability, and resilience is substantial.

Harvard’s work on soft robot muscles with an origami skeleton is pretty cool, right? It’s fascinating how these flexible structures are built. Learning about the intricate design process reminds me of the powerful tools available in software like adobe photoshop premiere pro ai creative agent actions for visual design. These tools can help you manipulate and enhance images and videos, just as the origami-inspired soft robot muscles offer a new approach to creating adaptable machines.

Overall, it’s a testament to how different fields can inspire and inform each other, especially in the realm of robotics.

Materials and Actuator Advancements

The performance of soft robots hinges critically on the materials used for both the muscles and the skeletal structures. Future research should investigate new bio-inspired materials with enhanced responsiveness, energy efficiency, and durability. This includes exploring polymers with tunable properties, composites that combine softness with strength, and hybrid systems incorporating conductive materials for advanced sensing and actuation. For instance, developing biocompatible materials for medical applications is crucial.

Control and Sensing Systems

Sophisticated control algorithms are essential for enabling complex movements and functionalities in soft robots. Research in this area should focus on developing methods to accurately monitor the robot’s internal state and adjust its behavior in real-time. This requires the integration of advanced sensors that can detect strain, pressure, and temperature within the soft muscles and origami skeleton. Examples include advanced sensors to measure and respond to changes in the environment.

Specific Application Development

The potential applications of soft robots with origami skeletons span a wide range of industries. Future research should concentrate on developing specialized designs for particular tasks. This includes tailoring the robot’s morphology and actuation system for specific environments. For example, designing soft robots for minimally invasive surgery, capable of navigating the human body with unprecedented precision, could revolutionize medical procedures.

Other examples include applications in agriculture and manufacturing.

Interdisciplinary Collaboration

The advancement of soft robotics requires a multidisciplinary approach. Future research should encourage collaborations between engineers, material scientists, biologists, and clinicians. This interdisciplinary collaboration can lead to innovative solutions and breakthroughs in fundamental understanding. For example, collaboration with biologists can lead to the development of soft robots that mimic biological systems, potentially leading to better medical devices.

Ethical Considerations

As soft robots become more sophisticated, ethical considerations regarding their use and deployment must be addressed proactively. Future research should include a strong ethical framework, considering potential societal impacts, safety concerns, and responsible development guidelines. This could involve establishing standards for safety, usage, and development to prevent misuse.

Illustrative Examples of Soft Robots

Soft robots, with their unique ability to adapt and interact with complex environments, are rapidly emerging as a powerful tool in various fields. Their flexible designs, often inspired by biological systems, allow them to navigate intricate spaces and perform tasks that traditional robots struggle with. This section will delve into specific examples, exploring their design, materials, and applications.

Soft Grippers for Delicate Objects

Soft grippers represent a significant advancement in handling delicate objects, such as eggs, fruits, and biological tissues. Their flexible nature prevents damage to the grasped items.

- Design: These grippers typically employ a network of interconnected pneumatic actuators or shape-memory polymers. The design is often inspired by the soft, enveloping nature of biological hands. They feature multiple, interconnected fingers or a continuous, soft surface that conforms to the object’s shape.

- Materials: Common materials include silicone rubber, elastomers, and specialized polymers with high stretchability and resilience.

The choice of material depends on the specific application and required properties like durability, biocompatibility, and responsiveness to stimuli.

- Functionality: The gripper’s flexibility allows it to gently grasp objects without crushing or damaging them. Sophisticated control systems enable precise manipulation and release of the object. Sensors integrated into the gripper provide feedback on the object’s pressure and position, enhancing control.

- Mechanism: Pneumatic actuators or shape-memory polymers are controlled to inflate or contract specific areas of the gripper, causing it to conform to the object’s shape. The actuators or polymers are often arranged in a network to provide complex motion and gripping patterns.

- Illustrative Image: Imagine a soft, hand-like gripper made of translucent silicone. It gently envelops a fragile, speckled egg, its contours perfectly matching the egg’s shape.

Tiny pressure sensors embedded in the gripper’s surface register the contact pressure, allowing for a precise and controlled grip. The gripper’s fingers slowly close around the egg, holding it firmly without crushing it. The entire process is smooth and precise, showcasing the delicate handling capability of the soft gripper.

Soft Robots for Medical Applications

Soft robots designed for medical applications aim to navigate the complex human body, offering minimally invasive solutions.

- Design: These robots often feature intricate, interconnected segments that can bend and flex to conform to the curves of the body. Their small size allows them to access narrow areas like blood vessels and airways.

- Materials: Biocompatible materials like hydrogels, biopolymers, and specialized elastomers are used to ensure the safety and compatibility with biological tissues.

- Functionality: These robots can perform a variety of tasks, including drug delivery, minimally invasive surgery, and tissue manipulation.

They can be guided to specific locations with precision and controlled movements.

- Mechanism: Soft robots in medical applications use a combination of pneumatic or electrostatic actuation, often controlled by intricate systems. They can have embedded sensors that provide real-time feedback on the surrounding environment and the robot’s performance.

- Illustrative Image: Visualize a snake-like robot made of a biocompatible, transparent hydrogel.

The robot navigates the complex network of blood vessels within a model of a human heart. The robot’s smooth, undulating movements allow it to move through the intricate vessels without causing damage. Embedded sensors track the robot’s position and provide real-time information to the surgeon, facilitating precise surgical intervention.

Soft Robots for Environmental Monitoring

Soft robots offer a unique advantage for environmental monitoring in challenging terrains and inaccessible locations.

- Design: These robots often mimic the flexibility and adaptability of living creatures, enabling them to navigate complex and uneven surfaces. They are often equipped with sensors to gather environmental data.

- Materials: Durable and resilient materials are used to withstand harsh environmental conditions.

- Functionality: These robots can collect data on temperature, humidity, and air quality in remote locations, or assess damage after natural disasters.

They can be used to inspect hard-to-reach areas.

- Mechanism: Their soft bodies and flexible joints allow them to navigate intricate terrain. Their control systems allow for the precise manipulation of their movements, enabling them to perform specific tasks.

- Illustrative Image: Imagine a soft, worm-like robot crawling across a rugged, rocky terrain. Sensors on its body measure the soil moisture content.

The robot’s movements are controlled by a remote system, allowing scientists to collect data from various points in the environment.

Closure

In conclusion, soft robot muscles origami skeleton mit harvard represent a significant leap forward in robotics. The integration of soft materials, origami principles, and innovative research paves the way for highly adaptable and versatile robots. While challenges remain, the potential for these robots to revolutionize various industries, from healthcare to manufacturing, is undeniable. This exciting field promises continued innovation and groundbreaking applications in the years to come.