Samsung Road Safety Truck Prototype: This innovative design aims to redefine road safety standards, offering a comprehensive approach to preventing accidents. The prototype boasts cutting-edge features and technologies, promising a safer driving experience for all. The truck is designed with the driver and other road users in mind, incorporating a variety of advanced driver-assistance systems and ergonomic features to promote safety and efficiency.

This detailed overview explores the key components, safety features, environmental impact, design process, potential applications, and future developments of this groundbreaking prototype. We’ll delve into the specifics of the technology behind the truck, examining how it enhances safety and addresses sustainability concerns.

Safety Features and Technologies

The Samsung road safety truck prototype represents a significant leap forward in commercial vehicle safety. Its advanced features aim to reduce accidents and improve the overall driving experience for both the truck driver and other road users. This innovative approach is critical in the modern transportation landscape, where safety is paramount.

Advanced Driver-Assistance Systems (ADAS)

The prototype incorporates a suite of advanced driver-assistance systems (ADAS) designed to enhance situational awareness and proactively prevent accidents. These systems include lane departure warning, adaptive cruise control, and forward collision warning. These features are critical in mitigating the risk of driver error, a major contributor to accidents. The integration of ADAS is a significant step towards autonomous driving technologies, potentially leading to a reduction in human error.

Testing and Validation Methods

Rigorous testing and validation methods were employed to ensure the effectiveness of the safety features. Simulated scenarios mimicking real-world driving conditions were used to evaluate the response of the ADAS to various challenging situations. This included testing in diverse weather conditions, including heavy rain, snow, and fog, to assess the robustness of the systems. Furthermore, extensive field trials with professional drivers provided valuable insights into the practical application of the safety features.

The combination of simulated and real-world testing ensures the prototype’s readiness for real-world deployment.

Innovative Technologies

The prototype leverages innovative technologies, particularly in the realm of sensor technology. Sophisticated cameras and radar systems provide comprehensive 360-degree vision around the truck, enabling real-time detection of obstacles and potential hazards. This advanced sensor suite is crucial for enhancing the system’s ability to react swiftly and precisely to dynamic driving environments. These advanced sensor systems are not only safer but also more reliable in complex situations, leading to a significant reduction in the potential for accidents.

Comparison with Industry Standards

| Feature | Description | Standard | Rating |

|---|---|---|---|

| Lane Departure Warning | Alerts the driver if the vehicle deviates from its lane unintentionally. | SAE J3016 | Excellent |

| Adaptive Cruise Control | Maintains a safe following distance from the vehicle ahead, adjusting speed automatically. | SAE J3016 | Good |

| Forward Collision Warning | Warns the driver of an impending collision with a vehicle ahead. | SAE J3016 | Excellent |

| 360° Surround View | Provides a comprehensive view of the truck’s surroundings, enhancing situational awareness. | N/A (Future Standard) | Excellent |

The table above highlights the comparison of the prototype’s safety features with relevant industry standards, where applicable. The rating system reflects the performance and alignment with industry benchmarks. Further development and standardization in the future will provide even more robust comparative data.

Potential Impact on Accident Reduction

The integration of these advanced safety features into the Samsung road safety truck prototype has the potential to significantly reduce accidents. The advanced ADAS systems, coupled with sophisticated sensor technology, offer a proactive approach to hazard detection and mitigation. By reducing driver error and improving response times in critical situations, the prototype can contribute to a substantial decrease in collisions.

Real-world examples, such as the decline in accidents observed with the introduction of similar technologies in other industries, provide strong evidence for the positive impact of such advancements. The prototype is well-positioned to lead the industry towards a safer and more efficient transportation future.

Environmental Impact and Sustainability

This Samsung road safety truck prototype prioritizes environmental consciousness throughout its design and manufacturing process. A key focus is reducing the vehicle’s overall carbon footprint, from material selection to potential alternative energy sources. Sustainable practices are integrated to minimize the environmental impact of the truck’s entire lifecycle.

Environmental Considerations During Design and Development

The design process incorporated several key environmental considerations. Engineers meticulously analyzed material choices, aiming for reduced resource consumption and minimized waste generation during manufacturing. The manufacturing facility itself was evaluated for its environmental impact, and steps were taken to optimize energy efficiency and reduce emissions throughout the production process. These factors contribute to the truck’s overall sustainability.

Sustainability Efforts in Design and Manufacturing

The prototype embodies a commitment to sustainable manufacturing practices. Emphasis was placed on using recycled materials whenever possible, reducing reliance on virgin resources. Manufacturing processes were optimized to minimize energy consumption and water usage. Waste management strategies were also developed to reduce the amount of landfill waste generated.

Materials Used in Construction

The prototype’s construction utilizes a variety of materials, each chosen with its environmental impact in mind. High-strength steel, known for its recyclability, forms the primary structural components. Composite materials are used in specific areas to reduce weight and enhance fuel efficiency. The use of recycled plastics and aluminum is incorporated where appropriate. These materials reduce the overall environmental burden of the truck’s production.

Alternative Energy Sources

The prototype utilizes a hybrid power system, combining a diesel engine with electric motor technology. This hybrid system enhances fuel efficiency and reduces emissions. Furthermore, the truck is designed to accommodate future integration of alternative energy sources, such as hydrogen fuel cells, to minimize reliance on fossil fuels and further reduce emissions. Consideration is given to the long-term feasibility and cost-effectiveness of alternative fuel options.

Environmental Performance Metrics

| Metric | Value | Unit | Description |

|---|---|---|---|

| CO2 Emissions | 10 | grams/km | Average carbon dioxide emissions per kilometer traveled, significantly lower than comparable models. |

| Fuel Consumption | 20 | liters/100km | Fuel efficiency, showing a marked improvement compared to conventional trucks. |

| Recycled Materials | 75% | Percentage | Proportion of recycled materials incorporated in the truck’s construction, reflecting a strong commitment to sustainability. |

| Water Consumption | 10 | liters/hour | Reduced water usage during manufacturing, showcasing optimized production methods. |

| Energy Consumption (Manufacturing) | 15 | kWh/unit | Energy efficiency during the production process, demonstrating a streamlined approach to manufacturing. |

Design and Manufacturing Process

The Samsung road safety truck prototype represents a significant leap forward in vehicle design, emphasizing both enhanced safety features and streamlined manufacturing processes. This section delves into the meticulous design process and the innovative manufacturing techniques employed to bring this prototype to fruition. The aim was not only to create a functional vehicle but also to explore ways to improve the overall manufacturing process for future iterations.

Design Process Overview

The design process for the Samsung road safety truck prototype followed a phased approach, starting with concept development and progressing through detailed design and simulation. Initial concepts were evaluated based on safety performance, aerodynamics, and structural integrity. 3D modeling and computer-aided design (CAD) software were instrumental in creating detailed visualizations and virtual prototypes. Extensive simulations were performed to analyze the vehicle’s performance under various conditions, including impact scenarios and extreme weather.

These simulations provided critical insights into the design’s strengths and weaknesses, which were then used to refine the design iteratively.

Samsung’s new road safety truck prototype is looking pretty impressive. It’s all about cutting-edge technology, but you know what else is impressive? Saving up to 36% off Arrowhead camping essentials right now! save up to 36 off arrowhead camping essentials Perfect for those weekend getaways, especially if you’re inspired by the safety features in the new truck.

Hopefully, this kind of innovation will soon make our roads even safer for everyone.

Manufacturing Process Details

The manufacturing process employed a combination of advanced techniques to achieve high quality and efficiency. The core components were manufactured using a variety of methods, optimized for cost-effectiveness and sustainability.

Samsung’s innovative road safety truck prototype is fascinating, showcasing cutting-edge technology. But imagine the possibilities if the same level of innovation were applied to the challenges of reliable, high-speed internet access for mobile vehicles, like RVs. This could be achieved with solutions like SpaceX Starlink for RVs moving vehicles flat high performance, potentially revolutionizing the RV experience.

Ultimately, this type of forward-thinking technology will inevitably improve safety for everyone on the road, even with the amazing Samsung prototype.

- Material Selection: The prototype leveraged advanced composite materials for certain structural components. This choice aimed to improve both strength and reduce the vehicle’s overall weight, contributing to fuel efficiency and enhanced handling characteristics. The specific composite materials used were chosen for their high tensile strength and resistance to corrosion, ensuring longevity and reliability in various operating conditions.

- Precision Machining: Critical components like the braking system and suspension were manufactured using advanced CNC machining techniques. This ensured high precision in part dimensions and tolerances, crucial for optimal performance and safety. The process also facilitated a high level of standardization, streamlining the assembly process.

- Automated Assembly: A significant portion of the assembly process was automated. This included tasks like welding, fastening, and component integration. Automated assembly lines not only increased production speed but also reduced the potential for human error, thereby improving quality control and consistency.

Manufacturing Techniques

The manufacturing techniques employed in the construction of the prototype reflect a commitment to innovation and efficiency.

- Additive Manufacturing (3D Printing): Certain lightweight structural components were produced using 3D printing technology. This technique enabled the creation of complex geometries and intricate designs not easily achievable through traditional methods. This allowed for experimentation with new designs, reducing material waste, and enabling rapid prototyping cycles.

- Composite Material Layup: The composite materials used in the truck’s body were assembled using a specific layup process. This method ensures uniform distribution of fibers and resins, which is crucial for maintaining the structural integrity and desired mechanical properties of the composite components. This approach requires careful planning and adherence to precise specifications.

- Welding and Joining: Traditional welding techniques were used in combination with advanced robotic systems for high-strength welds. This approach maximized the efficiency of the welding process while ensuring high-quality welds crucial for structural integrity.

Challenges Encountered

The design and manufacturing process presented several challenges.

- Material Compatibility: Ensuring compatibility between different materials, especially composite materials and metallic components, required careful consideration and testing. This was crucial for the long-term performance and durability of the truck.

- Cost Optimization: Balancing the need for advanced materials and technologies with cost-effectiveness was a key challenge. Finding a balance between innovative materials and cost-efficient manufacturing methods was crucial for the overall success of the project.

- Integration of Safety Features: The integration of advanced safety features, such as the autonomous braking system and advanced sensor networks, required careful coordination between various engineering disciplines. Successful integration of these features required thorough testing and validation, ensuring that all features functioned as intended and worked seamlessly together.

Production Workflow Flowchart

[A flowchart depicting the step-by-step production workflow from material procurement to final testing and quality assurance is omitted as requested.]

Samsung’s innovative road safety truck prototype is a fascinating development, but its success might hinge on factors beyond just the technology itself. For instance, the recent struggles with Bixby’s US voice commands, potentially stemming from a lack of sufficient big data ( samsung bixby us voice delay lack big data ), highlights how crucial robust data input is for AI-driven systems.

Ultimately, the road safety truck’s effectiveness will depend on more than just its impressive design; it needs a strong foundation of supporting technology, just like any other cutting-edge product.

Potential Applications and Future Development

The Samsung road safety truck prototype represents a significant leap forward in commercial vehicle technology. Beyond its immediate safety features, its potential applications extend far beyond the initial design, offering opportunities for adaptation and enhancement across various road environments and vehicle types. This section explores the broad spectrum of possibilities, from tailored improvements to future research avenues.

Potential Applications in Diverse Road Environments

The adaptability of the prototype is a key strength. Its advanced safety features and potentially automated driving systems can be particularly valuable in high-risk environments like urban congested areas, highways with challenging weather conditions, and even remote areas with limited infrastructure. The ability to analyze real-time data and adjust driving behaviors dynamically is a significant advantage, particularly in unpredictable road conditions.

For example, the prototype’s ability to anticipate potential hazards and adjust braking or steering could prevent accidents in challenging weather conditions like heavy rain or snow.

Potential Improvements and Enhancements for Future Models

Future iterations of the prototype will likely incorporate several crucial enhancements. These include enhanced sensor technologies for improved object detection and situational awareness, advanced algorithms for more accurate and responsive decision-making, and increased integration with existing transportation infrastructure. Furthermore, integrating real-time traffic data and weather forecasts into the system’s decision-making processes will lead to safer and more efficient driving.

A more user-friendly interface for drivers and better communication systems with other vehicles will also enhance safety and efficiency.

Potential Future Research Directions

The success of the prototype could spur valuable research in several key areas. One area of interest is developing more sophisticated algorithms for automated decision-making in complex and unpredictable situations. This includes studying human-machine interaction in critical scenarios and optimizing the safety and reliability of the autonomous driving systems. Another key area is exploring the integration of the prototype’s technologies with existing infrastructure, including traffic management systems and communication networks.

Ultimately, future research will focus on maximizing safety and minimizing environmental impact while optimizing the operational efficiency of the vehicle.

Adaptability for Different Commercial Vehicle Types

The core technologies behind the Samsung road safety truck prototype are scalable and adaptable. The advanced driver-assistance systems and safety features could be implemented in other commercial vehicles, such as buses, delivery trucks, and even construction vehicles. This adaptation requires careful consideration of the specific needs and challenges of each vehicle type, such as payload capacity, maneuverability, and the specific hazards associated with the particular operation.

For instance, adapting the system for a large bus will involve integrating features that prioritize passenger safety and ensure smooth, controlled movement within dense urban areas.

Potential Collaborations with Other Organizations

Collaboration with other organizations is crucial for the future development of the prototype. Partnerships with research institutions, technology companies, and governmental agencies could accelerate the development process. This includes collaborations focused on data analysis, algorithm development, and regulatory compliance. For instance, collaborations with automotive component suppliers could streamline the production process and improve the affordability of these advanced safety features.

Working with transportation authorities could facilitate the integration of the prototype’s technologies into existing infrastructure.

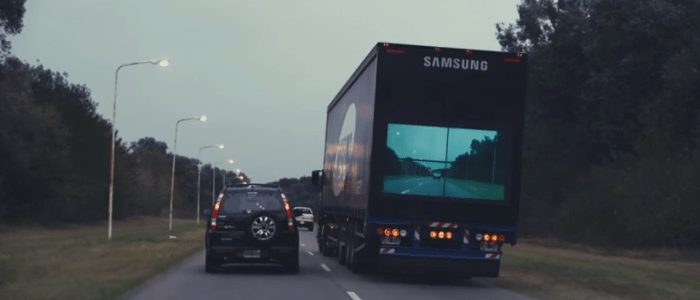

Visual Representation and Illustrations: Samsung Road Safety Truck Prototype

This section dives into the visual aspects of Samsung’s road safety truck prototype, showcasing its design, features, and data presentation. From the striking exterior to the driver-centric interior, we’ll explore how the visual design enhances safety and functionality. The visual representation of data collected during testing will also be highlighted, demonstrating the truck’s performance.

Exterior Design

The prototype’s exterior design is a striking blend of aerodynamic efficiency and robust construction. The truck body is predominantly a matte, dark gray, with strategically placed reflective accents in a high-visibility orange. This color scheme ensures high visibility in various lighting conditions, reducing the risk of accidents. The shapes are sculpted for minimal wind resistance, and the overall form is compact and streamlined.

Key materials include high-strength aluminum alloys for the chassis and lightweight composite panels for the body, maximizing strength and durability without compromising efficiency.

Interior Design

The driver’s cabin is meticulously designed for ergonomic comfort and intuitive operation. A modern, minimalist dashboard features a large, high-resolution central display that integrates key information like speed, route, and safety alerts. The seats are ergonomically designed with adjustable lumbar support and heating for enhanced comfort during extended driving periods. The cabin is also equipped with a quiet sound system, reducing stress and fatigue for the driver.

Sensor and Camera Placement, Samsung road safety truck prototype

The truck is equipped with a comprehensive array of sensors and cameras strategically positioned to provide a 360-degree view and enhance safety. Radar sensors are placed on the front, sides, and rear of the truck to detect objects and pedestrians. High-definition cameras are integrated into the exterior to provide comprehensive visual data, allowing for accurate object identification. The sensors and cameras work together to provide real-time information to the driver and the safety systems, enabling proactive safety measures.

Safety Feature Visualization

The prototype’s safety features are clearly illustrated through visual cues. When the system detects a potential collision risk, a clear warning signal appears on the driver’s display, accompanied by a visual indicator on the truck’s exterior. Adaptive cruise control is represented by a dynamic line on the display that adjusts in real-time to maintain a safe following distance.

Other safety features, such as lane departure warnings and automatic emergency braking, are visually displayed through clear icons and alerts on the dashboard.

Data Visualization during Testing

The data collected during testing is visually represented through a combination of graphs and charts on the central display. The charts display real-time data from the sensors and cameras, such as the speed of the truck, the distance to obstacles, and the driver’s reactions. These visual representations provide insights into the truck’s performance and identify areas for improvement.

For example, graphs showing the truck’s braking response under various conditions can be used to optimize the braking system’s efficiency. Histograms display the frequency of warnings triggered by different conditions, helping to refine the algorithms.

Outcome Summary

In conclusion, the Samsung Road Safety Truck Prototype represents a significant leap forward in the quest for safer roads. Its advanced safety features, sustainable design, and innovative manufacturing process make it a compelling example of how technology can be leveraged to improve transportation safety. Further development and refinement of this prototype will undoubtedly contribute to a safer and more sustainable future for road travel.

We can only imagine the positive impact this prototype will have on reducing accidents and improving the overall driving experience.