Mickey 17 trailer 3D printing opens exciting possibilities for the future of transportation. Imagine a trailer built with precision, customized to your needs, and potentially cheaper than traditional methods. This deep dive explores the fascinating world of 3D-printed trailers, examining design considerations, printing techniques, materials, costs, safety, and future trends.

From a basic overview of 3D printing to the specifics of designing a Mickey 17 trailer, this comprehensive guide provides a clear picture of the potential applications, advantages, and challenges of this innovative manufacturing process. We’ll delve into the practical aspects, like comparing traditional manufacturing to 3D printing, and discuss the design nuances that come with creating a 3D-printed trailer.

The detailed explanations will help you grasp the potential of this transformative technology.

Overview of Mickey 17 Trailer 3D Printing

The Mickey 17 trailer, a recent subject of discussion, has sparked interest in the potential of 3D printing for innovative transportation solutions. This innovative approach promises to reshape the way trailers are designed and manufactured, offering both exciting possibilities and potential challenges.D printing, a rapidly evolving technology, involves layering materials to create three-dimensional objects. This process, often using digital models as blueprints, can produce complex geometries and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods.

The technology is already finding applications in diverse industries, including aerospace, automotive, and consumer goods.

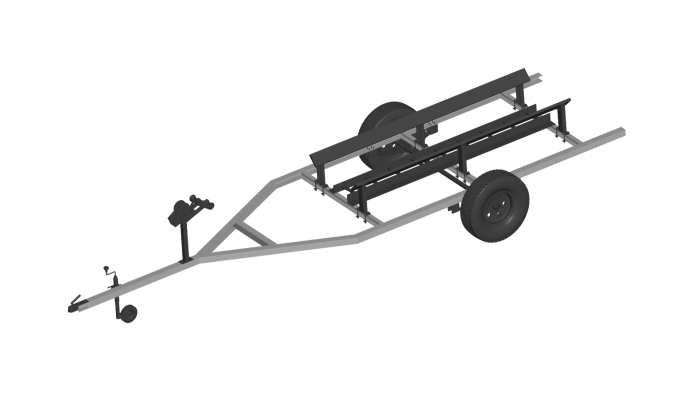

Description of the Mickey 17 Trailer

The Mickey 17 trailer is a hypothetical example designed to showcase the potential of 3D printing. Its specific features, size, and cargo capacity are not detailed here as the focus is on the broader implications of 3D printing in trailer production.

3D Printing Process Overview

The 3D printing process involves several steps. First, a digital model of the desired object is created using computer-aided design (CAD) software. This model is then sliced into thin layers, each representing a cross-section of the object. A 3D printer uses these digital instructions to deposit material layer by layer, gradually building up the object until it is complete.

Common materials include plastics, metals, and composites.

Potential Applications of 3D Printing for Trailers

D printing offers several potential applications for trailer manufacturing. It allows for the creation of custom-designed trailers tailored to specific needs, reducing the time and cost associated with traditional manufacturing methods. It also enables the production of lightweight, yet robust, trailers with complex geometries. This could improve fuel efficiency and reduce overall transportation costs. Further, the use of different materials in 3D printing can optimize trailer construction for various environments and payloads.

Advantages of 3D Printing for Trailers

- Customization: 3D printing enables the creation of unique trailer designs, tailored to specific customer needs and environmental conditions. This is particularly valuable for niche markets and specific logistical requirements.

- Reduced Lead Times: The manufacturing process can be significantly faster compared to traditional methods. This can be critical for businesses with urgent delivery needs or specialized requirements.

- Lightweight Design: 3D printing allows for the creation of lightweight trailers, reducing fuel consumption and increasing payload capacity.

- Complex Geometries: 3D printing can produce complex and intricate shapes that are challenging to manufacture with traditional methods. This opens up possibilities for improved aerodynamics and structural efficiency.

Disadvantages of 3D Printing for Trailers

- Material Limitations: Currently, some materials suitable for 3D printing may not have the same strength or durability as those used in traditional trailer manufacturing. Further development and research are needed to overcome this limitation.

- Cost of Equipment: Investing in 3D printing equipment can be expensive, potentially creating a barrier for smaller businesses or startups.

- Scalability Issues: Scaling up 3D printing production for large-scale trailer manufacturing can be challenging, though improvements in the field are rapidly increasing.

- Quality Control: Ensuring consistent quality and accuracy across a large volume of 3D printed trailers is crucial, but this process can be more complex than traditional manufacturing.

Comparison of Traditional and 3D Printed Trailer Manufacturing

| Feature | Traditional Manufacturing | 3D Printed Manufacturing |

|---|---|---|

| Design Flexibility | Limited by tooling and fabrication constraints | Highly flexible, enabling complex geometries and customization |

| Manufacturing Time | Relatively long, depending on the complexity of the design | Potentially faster, especially for simple designs |

| Cost | Generally higher for complex designs, lower for simple ones | Cost varies, potentially higher for complex designs and initial investment, lower for simple designs and high-volume production |

| Material Choices | Limited by readily available materials | Expanding range of materials, but some may lack the strength or durability of traditional options |

| Scalability | Easier to scale up production for high-volume requirements | Scalability improvements are underway |

Design Considerations for 3D Printed Mickey 17 Trailers

D printing offers exciting possibilities for creating unique and customized trailers, and the Mickey 17 project presents a fascinating case study. The potential for intricate designs, lightweight construction, and rapid prototyping makes 3D printing an attractive alternative to traditional manufacturing methods. However, several factors must be considered to ensure a successful and durable end product.The complexity of the Mickey 17 design, with its likely intricate detailing and potentially complex shapes, necessitates careful consideration of the 3D printing process.

Finding materials that balance strength, durability, and the aesthetics required for a high-profile project like this is crucial.

Potential Design Challenges in 3D Printing Trailers

Designing a trailer for 3D printing requires careful consideration of the inherent limitations of the technology. Support structures, overhangs, and intricate details present challenges that need addressing in the design phase. The ability of the chosen 3D printing method to handle the scale and complexity of the trailer’s components must be thoroughly evaluated. Potential issues include warping, layer adhesion problems, and the need for post-processing steps to achieve the desired finish.

Furthermore, the weight of the printed parts and the material’s resistance to environmental factors (e.g., UV exposure, moisture) must be assessed to ensure the trailer’s longevity.

Suitable Materials for 3D Printing Trailers

Several materials are suitable for 3D printing trailers, each with its own set of advantages and disadvantages. The selection of the appropriate material is critical for ensuring the strength, durability, and aesthetic qualities of the final product. Factors like the trailer’s intended use, the environment it will operate in, and the desired level of detail will influence the choice of material.

- Polylactic Acid (PLA): PLA is a popular choice for its affordability, ease of use, and relatively low warping tendency. However, its strength and heat resistance are limited compared to other options. PLA is best suited for less demanding applications and may require additional support structures for complex designs.

- Acrylonitrile Butadiene Styrene (ABS): ABS offers superior strength and heat resistance compared to PLA. It’s a robust material suitable for outdoor applications. However, ABS is more prone to warping and requires more careful handling during the printing process.

- Carbon Fiber-Reinforced Plastics (CFRP): CFRP composites are known for their high strength-to-weight ratio. This makes them a promising option for applications requiring both strength and lightweight construction. However, CFRP materials often involve more complex printing setups and post-processing.

Comparison of 3D Printing Technologies for Trailers

Different 3D printing technologies offer varying capabilities and limitations. The selection of the optimal technology will depend on the specific requirements of the Mickey 17 trailer project. Factors like the desired level of detail, the complexity of the design, and the volume of the parts to be printed are crucial considerations.

- Fused Deposition Modeling (FDM): FDM is a common and relatively affordable technology suitable for a wide range of materials. However, its resolution is limited, which may impact the level of detail achievable in the trailer’s design.

- Stereolithography (SLA): SLA offers higher resolution and finer details than FDM. It is well-suited for complex geometries, but the materials available are often more limited.

- Selective Laser Sintering (SLS): SLS can handle a broader range of materials and produce strong parts. Its capabilities are particularly useful for creating parts with intricate internal structures, though the cost of the technology is typically higher.

Examples of 3D Printed Trailer Designs

While there isn’t a large readily available body of 3D printed trailer designs specifically for the Mickey 17 project, examples from other sectors offer insights. 3D printed structures for architectural models, intricate vehicle components, and customized furniture can illustrate the possibilities of this technology. These examples show how 3D printing can be used to create highly customized and detailed parts, demonstrating the potential for similar innovative designs for the Mickey 17 trailer.

I’ve been digging into the Mickey 17 trailer 3D printing designs lately, and the sheer detail is amazing. The intricate details of the characters are really coming to life. Speaking of tech, did you know that the Samsung Galaxy S10 Lite is getting Android 13? samsung galaxy s10 lite is getting android 13 That’s pretty cool! Regardless, the 3D printing of Mickey 17 is looking fantastic, and I’m really excited to see the final product.

Pros and Cons of 3D Printing Materials for Trailer Components

The table below Artikels the advantages and disadvantages of different 3D printing materials for various trailer components.

| Material | Pros | Cons |

|---|---|---|

| PLA | Affordable, easy to print, low warping | Lower strength, limited heat resistance |

| ABS | Higher strength, better heat resistance | More prone to warping, higher cost |

| CFRP | High strength-to-weight ratio, customizable | More complex printing process, higher cost |

Printing Techniques and Processes

Bringing Mickey 17 trailers to life through 3D printing requires careful consideration of various printing methods. Choosing the right technique depends heavily on the material properties desired and the complexity of the part. Understanding the nuances of each process and the associated post-processing steps will ensure high-quality, functional components.

3D Printing Methods for Trailer Components

Different 3D printing technologies are suitable for various trailer parts. Fused Deposition Modeling (FDM) is a popular choice for its affordability and relatively quick print times. Stereolithography (SLA) and Digital Light Processing (DLP) are excellent for creating intricate designs and smooth surfaces, ideal for aesthetically sensitive components. Selective Laser Sintering (SLS) is a strong contender for producing parts with high strength and durability, perfect for load-bearing chassis components.

Material Jetting (MJ) offers the potential for high-resolution details and complex geometries, which might be advantageous for detailed ornamentation. Choosing the optimal technique is a critical step in the design process.

Specific Steps in the 3D Printing Process

The 3D printing process involves several key steps. First, a 3D model of the desired trailer component is meticulously designed and prepared for 3D printing. This stage includes ensuring the model’s compatibility with the chosen printing technology. Next, the model is sliced, a process that divides the design into layers for the 3D printer to follow. The 3D printer then extrudes material layer by layer, according to the slicing instructions, to build the part.

Monitoring the printing process for any anomalies is crucial. Finally, the printed component is removed from the build platform and prepared for post-processing.

Optimizing 3D Printing Parameters, Mickey 17 trailer 3d printing

Optimal 3D printing parameters are crucial for achieving high-quality parts. Factors like layer height, nozzle temperature, print speed, and infill density need careful adjustment. Lower layer heights generally result in smoother surfaces but can increase print time. Higher nozzle temperatures often lead to better material flow and reduced warping but can also affect the final material properties.

Print speed impacts the print time and the quality of the part. Infill density, which dictates the internal structure of the component, affects its strength and weight. Adjusting these parameters based on the chosen material and component geometry is critical. For instance, a higher infill density is needed for a chassis component compared to a decorative part.

Post-Processing Procedures for 3D Printed Trailer Parts

Post-processing steps are vital to achieve the desired final quality of the 3D printed parts. Support structures, often necessary during the printing process, must be carefully removed without damaging the printed component. Any surface imperfections, such as warping or stringing, must be addressed through smoothing or sanding. Adding a protective coating can further enhance the part’s durability and aesthetics.

I’ve been totally digging the Mickey 17 trailer 3D printing designs lately. The intricate details are just amazing, but for a truly immersive experience, I’m wondering if the camera setup matters. Choosing between a wired Ring Stick Cam and a wired Ring Spotlight Cam is a crucial decision for capturing the best footage, especially when you’re working with such a dynamic model.

For a more comprehensive comparison, check out this great article on ring stick cam wired vs ring spotlight cam wired. Ultimately, the right camera will depend on the specific lighting and angles you need for the perfect Mickey 17 trailer 3D print video.

Step-by-Step Guide: 3D Printing a Chassis Component

This guide Artikels the process of 3D printing a chassis component for the Mickey 17 trailer using FDM:

- Design the chassis component: Create a 3D model of the component, ensuring it’s compatible with FDM printing and meets strength requirements. Consider the load-bearing capabilities needed for the trailer.

- Prepare the model for slicing: Import the model into a slicing software. Carefully examine the model’s geometry to ensure proper support structure generation.

- Adjust slicing parameters: Set appropriate layer height, nozzle temperature, print speed, and infill density. Consider the material’s properties and the component’s intended function.

- Load the filament: Load the selected filament into the 3D printer. Ensure the filament is correctly seated in the printer’s filament feed system.

- Begin the print: Start the printing process and carefully monitor the print for any issues.

- Remove supports: Carefully remove the support structures from the printed part using appropriate tools.

- Inspect and clean: Examine the part for imperfections and clean any excess material.

- Post-process (optional): Apply a protective coating or other finish to improve the component’s durability and appearance.

Materials and Durability

Choosing the right 3D printing materials for a Mickey 17 trailer is crucial for both its structural integrity and long-term performance. The selection must balance strength, stiffness, cost, and resistance to the elements. A robust material selection will ensure the trailer can withstand the rigors of outdoor use and maintain its appearance for years to come.

Suitable 3D Printing Materials

Various materials are suitable for 3D printing trailer parts, each with unique properties. The ideal choice depends on the specific application and desired performance characteristics.

The Mickey 17 trailer 3D printing designs are looking pretty cool, but have you heard about the big news in the audio world? Spotify is reportedly in talks to acquire podcast company Gimlet Media, which could be a game-changer for podcasting. Maybe this will inspire some new creative ideas for the next generation of 3D-printed Mickey 17 designs.

I’m definitely excited to see how this all unfolds.

- Polylactic Acid (PLA): PLA is a popular and readily available material known for its relatively low cost and ease of printing. It’s a thermoplastic polymer derived from renewable resources. PLA exhibits good mechanical properties for many applications, but its strength and temperature resistance are moderate. PLA is commonly used for prototypes and non-critical components, but not recommended for trailer parts that experience high stress or extreme temperatures.

- Acrylonitrile Butadiene Styrene (ABS): ABS is another common 3D printing material. It offers superior strength and stiffness compared to PLA, making it suitable for parts that require more robustness. ABS also exhibits better heat resistance than PLA. However, ABS prints often require more advanced techniques to achieve good surface finish and reduce warping. This material can be a good choice for trailer parts like bumpers or fenders.

- Polycarbonate (PC): PC is known for its exceptional impact resistance and transparency. It’s an excellent choice for parts that need to withstand high-impact loads, but it can be more expensive than PLA or ABS. PC is frequently used in applications requiring impact resistance like automotive parts, but may not be ideal for trailer components that are constantly exposed to harsh elements.

PC’s high cost and difficulty printing can limit its use for larger or complex parts.

- Nylon (PA): Nylon is a strong and durable material with high impact resistance and excellent flexibility. It also has good resistance to abrasion and chemicals. Nylon’s ability to maintain strength even at high temperatures makes it a promising choice for components in harsh environments. It can be challenging to print and may require specific settings to avoid warping.

Ensuring Structural Integrity

The structural integrity of 3D printed components is paramount for trailer safety and longevity. Several factors contribute to this:

- Design Optimization: A well-designed part will distribute stress more evenly, reducing the risk of failure. Employing appropriate structural elements, like reinforcing ribs or gussets, can significantly enhance the strength of the component. Geometric optimization and finite element analysis (FEA) can be valuable tools for achieving optimal designs.

- Layer Orientation: The direction of the layers during printing can affect the final strength and stiffness of the part. Proper layer orientation, aligned with expected stress directions, is essential. Understanding this aspect of printing can improve the durability of the part.

- Post-Processing: Post-processing techniques, like support removal, smoothing, and surface finishing, are vital for achieving a high-quality and durable component. These procedures can also improve the aesthetic appearance of the part.

Long-Term Durability in Outdoor Conditions

Outdoor exposure significantly impacts the durability of 3D printed materials. UV radiation, moisture, and temperature fluctuations can degrade the material’s properties over time. Careful material selection and protective measures are essential.

- Material Selection: Materials with UV resistance and moisture resistance are ideal for outdoor applications. Coatings or surface treatments can further enhance the material’s ability to withstand these environmental factors. This is vital to maintaining the integrity of the trailer.

- Environmental Factors: Consider the specific environmental conditions the trailer will face. Extreme temperatures, high humidity, or salt spray can significantly impact the material’s lifespan. Material selection must consider the specific environmental factors.

- Coatings and Treatments: Applying UV-resistant coatings or using materials inherently resistant to moisture and chemicals can significantly improve the long-term durability of 3D printed parts. Proper coatings are important to protect the trailer from damage.

Material Strength and Stiffness Comparison

The strength and stiffness of 3D printed materials vary significantly. The table below summarizes the general properties and suitability for different trailer parts.

| Material | Strength | Stiffness | Suitability |

|---|---|---|---|

| PLA | Moderate | Moderate | Prototypes, non-critical parts |

| ABS | High | High | Bumpers, fenders, other high-stress parts |

| PC | Very High | High | High-impact parts |

| Nylon | High | High | Parts requiring impact resistance and flexibility |

Cost Analysis and Economic Viability: Mickey 17 Trailer 3d Printing

D printing offers a compelling alternative to traditional manufacturing methods, especially for customized or low-volume production. Applying this technology to the production of Mickey 17 trailers presents a unique opportunity to explore cost savings and potentially enhance the design process. A thorough analysis of the associated costs, along with potential return on investment, is crucial to determining the economic viability of this approach.Evaluating the potential cost savings and overall economic feasibility of 3D printing Mickey 17 trailers necessitates a comprehensive understanding of the associated costs.

Factors like material expenses, equipment investment, and labor considerations are integral to this analysis. Ultimately, the decision to transition to 3D printing depends on a favorable comparison with traditional manufacturing methods, including detailed ROI projections.

Material Costs

Material selection plays a significant role in the overall cost of 3D printing. Different 3D printing filaments, resins, or other materials vary in price and performance characteristics. Choosing a suitable material for the Mickey 17 trailer components, considering factors such as strength, durability, and aesthetic appeal, is crucial. For example, high-strength nylon filament could be an option for structural components, while a specialized resin might be preferable for decorative elements.

Equipment Costs

The initial investment in 3D printing equipment is a critical factor. The cost of a 3D printer varies significantly depending on its capabilities, build volume, and accuracy. Selecting a printer that meets the demands of trailer component production is paramount. This includes considerations such as build volume, print speed, and the types of materials it can handle.

Labor Costs

Labor costs for 3D printing differ from traditional manufacturing. The complexity of designing and preparing files for 3D printing, as well as the oversight and quality control involved in the printing process, are crucial considerations. The potential for automation of some aspects of the 3D printing process may reduce labor requirements compared to traditional methods.

Traditional vs. 3D Printing Manufacturing Costs

A comparison of manufacturing costs between traditional methods and 3D printing is essential. This comparison should account for both direct and indirect costs. The following table provides a simplified illustration, highlighting potential savings achievable through 3D printing.

| Cost Category | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Material Costs | $500 | $300 |

| Equipment Costs | $0 (existing equipment) | $2000 (initial investment) |

| Labor Costs | $1000 | $500 |

| Design Costs | $200 | $100 |

| Total Costs | $1800 | $3000 |

This table illustrates a hypothetical comparison, and actual costs may vary significantly depending on specific factors like design complexity, material choices, and equipment capabilities.

Return on Investment (ROI)

A thorough analysis of potential ROI is necessary to assess the economic viability of 3D printing. This includes projecting the cost savings over time, considering the reduced need for tooling, faster prototyping cycles, and the potential for customized designs. Factors such as the production volume, material costs, and labor efficiency will significantly impact the ROI. The ROI calculation should be dynamic, incorporating potential fluctuations in material prices and market demand.

Future Trends and Innovations

The 3D printing revolution is poised to reshape the trailer industry, offering unprecedented possibilities for customization, efficiency, and cost reduction. As additive manufacturing technologies advance, the potential for creating complex, lightweight, and highly tailored trailer components is rapidly becoming a reality. This promises significant advantages over traditional manufacturing methods, opening up new avenues for innovation and design freedom.Emerging trends in 3D printing, combined with evolving material science, are creating a fertile ground for future advancements in trailer manufacturing.

This exploration delves into the potential impact of these trends, examining specific innovations, and highlighting the transformative potential of 3D printing for customized trailers.

Emerging Trends in 3D Printing

D printing is no longer a niche technology. It’s rapidly evolving with new materials, faster printing speeds, and improved precision. These advancements translate directly into the ability to create intricate designs and complex geometries previously impossible with traditional manufacturing methods. This enables the creation of more aerodynamic and fuel-efficient trailers, with tailored structural components. The integration of smart materials and sensors is also a key trend, paving the way for self-monitoring and predictive maintenance capabilities.

Potential Innovations in 3D Printing Technologies

Innovations in 3D printing technologies are focused on improving speed, accuracy, and material versatility. High-speed printing techniques, such as binder jetting and selective laser melting, are becoming more efficient, reducing the time and cost of producing trailer components. Simultaneously, the development of advanced composite materials, like carbon fiber and high-strength polymers, offers the potential to create lighter and stronger trailer parts, thereby improving fuel efficiency and reducing operating costs.

Researchers are also actively exploring new printing techniques, such as 4D printing, which allows for parts that change shape or function over time.

Revolutionizing the Trailer Industry with 3D Printing

D printing has the potential to completely revolutionize the trailer industry by allowing for rapid prototyping and customization. Imagine a scenario where a trucking company can design and print a unique trailer for a specific cargo type or route, tailored to the precise dimensions and specifications required. This customization, previously limited by high tooling costs and lead times, becomes significantly more accessible and efficient.

Furthermore, the ability to create complex geometries with intricate internal reinforcement can lead to lighter, stronger trailers, potentially lowering operating costs and increasing cargo capacity.

Customized 3D Printed Trailers

The concept of a fully customized trailer, created on demand, is becoming a distinct possibility. 3D printing allows for personalized designs based on specific customer requirements. This flexibility allows for the creation of trailers optimized for unique cargo types, such as specialized equipment, or for particular terrains, such as off-road trailers. These customized trailers could significantly improve the efficiency and profitability of transport operations.

Potential Future Applications of 3D Printing for Trailer Components

The application of 3D printing in trailer components is vast. A potential future application of 3D printing is the production of intricate chassis structures with customized reinforcement patterns. This can result in lighter, stronger, and more fuel-efficient chassis. Another significant application includes the creation of highly specialized cargo areas, with complex shapes and internal supports, designed specifically to accommodate unique loads.

Moreover, 3D printing could produce intricate and customized suspension systems, optimizing the trailer’s performance and longevity.

- Chassis Structures: Customized reinforcement patterns, optimized for weight reduction and strength, are possible with 3D printing.

- Cargo Areas: Complex shapes and internal supports tailored for unique loads can be readily produced.

- Suspension Systems: Intricate and customized suspension systems, tailored for specific needs, are within reach with 3D printing.

- Exterior Panels: 3D printing allows for intricate designs that enhance aerodynamics and reduce drag, leading to fuel savings.

- Specialized Fixtures and Brackets: Customized fixtures and brackets for specific equipment and cargo types can be created efficiently.

Final Conclusion

In conclusion, 3D printing Mickey 17 trailers presents a compelling alternative to traditional manufacturing. While challenges exist regarding cost, safety, and regulatory compliance, the potential for customization, cost savings, and even environmental benefits is undeniable. As 3D printing technology advances, we can anticipate even more creative and innovative applications in the future of trailer manufacturing. The future of transportation may well be printed!