Made in USA is harder than Trump thinks. The promise of bringing manufacturing back to the US, a cornerstone of Trump’s economic agenda, faces significant obstacles. From the complexities of supply chains to the persistent labor shortages, the reality of reviving domestic production is proving more challenging than initially envisioned. This deep dive examines the hurdles, Trump’s policies, and the broader economic factors impacting this crucial initiative.

This analysis explores the multifaceted challenges facing the “Made in USA” movement, considering manufacturing difficulties, the effects of Trump’s trade policies, and the influence of global economic forces. We’ll also delve into public perception and the potential solutions for bolstering domestic production.

Manufacturing Challenges in the USA

The “Made in USA” initiative faces significant hurdles in regaining a prominent position in the global manufacturing landscape. While there’s a growing desire to support domestic production, overcoming entrenched challenges requires a comprehensive understanding of the obstacles and a proactive approach to addressing them. The complexities of supply chains, labor shortages, and differing costs of production all contribute to a complex picture for US manufacturers.The transition to “Made in USA” is not a simple reversal of globalization.

It requires a multifaceted strategy that addresses not only the immediate costs and logistics but also the long-term development of American manufacturing infrastructure. The effort to reshore production must consider the nuances of various industries, the varying needs of different supply chains, and the long-term skills development needed to sustain this transition.

Obstacles to Increasing Domestic Manufacturing

The path to increasing domestic manufacturing in the USA is fraught with obstacles. These range from historical investments in foreign production to contemporary issues such as supply chain fragility and labor market dynamics. The transition is not just about relocating existing facilities; it necessitates a profound re-evaluation of the entire manufacturing ecosystem.

Specific Industries Facing Challenges

Several industries face significant hurdles in shifting production to the US. The automotive sector, heavily reliant on global supply chains, has struggled to fully transition to domestic sourcing. Similarly, the electronics industry, with its intricate global supply networks, experiences considerable difficulties in localizing production. These industries, along with others like aerospace and pharmaceuticals, require extensive adjustments to shift their reliance away from foreign suppliers.

Key Factors Hindering US Manufacturing Growth

Several key factors contribute to the slowdown in US-based manufacturing. The high cost of labor in comparison to some foreign competitors, combined with the complexities of navigating the American regulatory environment, creates a formidable challenge for US-based manufacturers. The lack of skilled labor and the increasing difficulty in attracting and retaining skilled workers are critical issues. Moreover, infrastructure limitations, such as outdated facilities and insufficient transportation networks, further impede growth.

Supply Chain Disruptions and Their Impact

Supply chain disruptions have significantly impacted “Made in USA” efforts. The COVID-19 pandemic exposed vulnerabilities in global supply chains, highlighting the necessity for resilience and diversification. Manufacturers now need to consider more geographically diverse sourcing to mitigate future disruptions. The reliance on just-in-time inventory management systems also proved problematic, demonstrating the need for more robust, domestically-focused strategies.

Labor Shortages and Skill Gaps

Labor shortages and skill gaps pose a critical impediment to domestic manufacturing growth. The current labor market demands skilled workers with specific technical expertise in areas like robotics, automation, and advanced manufacturing processes. This skill gap needs to be addressed through educational programs, apprenticeship initiatives, and workforce training to create a skilled domestic workforce.

Cost Comparison of US and Foreign Manufacturing

| Factor | US Manufacturer | Foreign Manufacturer |

|---|---|---|

| Labor Costs | Higher | Lower |

| Material Costs | Potentially higher or lower depending on source and availability | Potentially lower |

| Transportation Costs | Potentially higher depending on location and infrastructure | Potentially lower |

| Regulatory Costs | Potentially higher due to compliance requirements | Potentially lower due to less stringent regulations in some cases |

The table above provides a general comparison. Specific costs will vary considerably based on the industry, location, and specific circumstances of the manufacturing operation.

Trump’s Policies and Their Impact

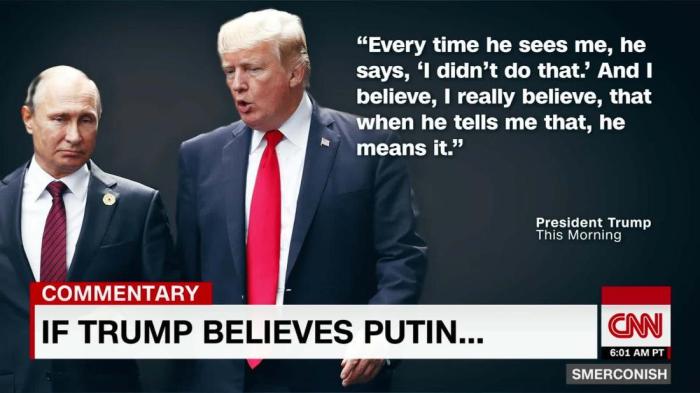

Donald Trump’s presidency saw a significant shift in US trade policy, with a focus on “Made in USA” initiatives. While the stated goals were to bolster American manufacturing and protect domestic jobs, the actual outcomes and effects are complex and often debated. This analysis examines the stated objectives, the practical results, and the potential consequences of these policies.The “America First” approach, central to Trump’s trade agenda, aimed to reduce US trade deficits and bring back manufacturing jobs.

This involved a variety of measures, including tariffs on imported goods and renegotiation of existing trade agreements. The intended result was a more balanced trade relationship and greater economic prosperity for the United States. However, the long-term impacts are still unfolding, with arguments on both sides about the effectiveness of these policies.

Trump’s “Made in USA” push seems tougher than he anticipated. Recent news about the Xiaomi blacklist removal, a company with alleged ties to the Communist Chinese military ( xiaomi blacklist removed communist chinese military company ), highlights the complex web of global supply chains. This underscores just how intricate and challenging the ‘Made in USA’ goal actually is.

Stated Goals of Trump’s Trade Policies

Trump’s administration aimed to reduce the trade deficit by imposing tariffs on imported goods, particularly from China. The goal was to make American-made products more competitive in the domestic market, thus encouraging domestic production. The administration also aimed to renegotiate trade agreements, like NAFTA, to secure more favorable terms for the US. This involved reducing reliance on foreign manufacturing and creating a more robust domestic manufacturing sector.

Comparison of Proposed Policies to Actual Outcomes

While Trump’s administration argued that tariffs would protect American jobs and reduce trade deficits, the actual outcomes were more nuanced. The tariffs imposed on various imported goods led to price increases for consumers, and some studies suggest that the impact on job creation was limited or even negative in certain sectors. The renegotiation of trade agreements, such as the USMCA (United States-Mexico-Canada Agreement), also faced challenges, and the overall impact on US trade balances is still subject to ongoing analysis.

Trade Policies Implemented Under Trump’s Administration

| Policy | Description | Target Country/Region |

|---|---|---|

| Tariffs on Steel and Aluminum | Imposition of tariffs on imported steel and aluminum from various countries. | Multiple countries |

| Tariffs on Chinese Imports | Imposition of tariffs on a wide range of Chinese goods. | China |

| Renegotiation of NAFTA | Rewriting the North American Free Trade Agreement. | United States, Mexico, and Canada |

| Trade Disputes with China | Escalation of trade tensions with China, resulting in numerous rounds of tariffs. | China |

Overview of Trade Wars Initiated During Trump’s Presidency

The Trump administration engaged in significant trade disputes, primarily with China, leading to escalating tariffs and retaliatory measures. These disputes involved numerous rounds of tariff increases and decreases, impacting global trade and supply chains. These actions created uncertainty for businesses and consumers, with the potential for negative ripple effects. The trade wars created significant volatility in global markets and influenced international relations.

Potential Consequences of Protectionist Policies on US Consumers

Protectionist policies, such as tariffs, can lead to higher prices for consumers as import costs are passed on to the final product. Reduced competition from foreign producers may also lead to less choice and innovation in the domestic market. The impact on specific consumer goods, from electronics to clothing, can be substantial, affecting various income levels. Supply chain disruptions and potential shortages of essential goods are also potential consequences.

Pros and Cons of Trade Policies Enacted by Trump

| Pros | Cons |

|---|---|

| Potential for increased domestic production in certain sectors. | Higher prices for consumers due to tariffs. |

| Potential for job creation in protected industries. | Disruption of global supply chains and reduced trade. |

| Increased bargaining power in trade negotiations. | Negative impact on international relations and trade partners. |

| Focus on national interests and reduced trade deficit. | Uncertainty and volatility in global markets. |

Economic Factors Affecting ‘Made in USA’: Made In Usa Is Harder Than Trump Thinks

The resurgence of “Made in USA” initiatives faces significant economic headwinds. Understanding these factors is crucial for crafting effective strategies to bolster domestic manufacturing and ensure its competitiveness in the global market. Fluctuating exchange rates, global economic conditions, and technological advancements all play pivotal roles in shaping the success of US-made goods. Analyzing these factors, and the resulting challenges and opportunities, is key to formulating strategies that can sustain and grow the domestic manufacturing sector.The economic landscape surrounding manufacturing is complex and dynamic.

Factors such as fluctuating exchange rates, global economic downturns, technological advancements, and the comparative cost of production all significantly impact the viability and competitiveness of US-made goods. Government policies, particularly subsidies and tax incentives, play a vital role in mitigating these challenges and fostering domestic manufacturing.

Fluctuating Exchange Rates and Competitiveness

Fluctuations in currency exchange rates directly affect the price competitiveness of US-made goods in international markets. A stronger US dollar makes American exports more expensive, potentially reducing demand and impacting export-oriented manufacturers. Conversely, a weaker dollar makes US goods cheaper for foreign buyers, boosting demand and increasing export revenues. This constant interplay necessitates careful monitoring and adaptation by US manufacturers.

For example, a significant appreciation of the US dollar against the Euro could make US-produced automobiles less attractive to European consumers, thereby impacting export volumes.

Impact of Global Economic Conditions

Global economic downturns and uncertainties have a ripple effect on US manufacturing. Recessions in key trading partners can lead to decreased demand for US exports, impacting production levels and employment in the affected sectors. Furthermore, geopolitical instability and trade conflicts can disrupt supply chains and add further complexity to the economic landscape for US manufacturers. For instance, the 2008 financial crisis led to a significant decline in global demand, causing production cuts and job losses across various manufacturing sectors in the United States.

Influence of Automation and Technology

Automation and technological advancements are reshaping the US manufacturing sector. These technologies enhance productivity, efficiency, and quality control, but they also present challenges related to workforce adaptation and potential job displacement. The implementation of robotic automation in assembly lines, for example, can dramatically increase output and reduce labor costs, but it also necessitates retraining programs to equip workers with the skills needed to operate and maintain these advanced systems.

The adoption of 3D printing technologies has enabled the creation of customized and complex products, fostering greater flexibility in manufacturing processes.

Honestly, “Made in USA” is proving a lot tougher than President Trump predicted. While a great coffee machine can make a good morning, you can snag a fantastic deal on a Nespresso Vertuo Next Deluxe coffee and espresso machine, saving a whopping $49 with a 25% discount. get 25 off this Nespresso Vertuo Next Deluxe coffee and espresso machine save 49 It’s clear that revitalizing American manufacturing is a much more complex challenge than some initially thought.

Comparison of Manufacturing Costs and Efficiency

Manufacturing costs and efficiency differ significantly between US and foreign producers. Factors such as labor costs, energy prices, and access to raw materials contribute to these disparities. While US workers may have higher wages than those in some developing nations, US manufacturers often benefit from advanced infrastructure and access to sophisticated technology, which can potentially offset some labor cost differences.

The overall efficiency of production processes is also impacted by factors such as regulatory environments, transportation costs, and supply chain logistics.

Importance of Government Subsidies and Tax Incentives

Government subsidies and tax incentives can play a crucial role in supporting domestic manufacturing. These initiatives can help reduce production costs, encourage investment in new technologies, and promote innovation within the sector. Specific incentives, such as tax credits for research and development or grants for energy-efficient equipment, can help offset some of the disadvantages faced by US manufacturers in the global market.

For instance, the US government provides various tax credits and grants to stimulate investment in renewable energy technologies.

Trump’s “Made in USA” push is proving tougher than he anticipated. While the White House denies reports of Elon Musk’s national security reviews ( white house denies report of musk national security reviews ), the complexities of global supply chains and manufacturing are highlighting the inherent difficulties in truly achieving domestic production goals. It’s a whole lot harder than many imagined, which makes that “Made in USA” slogan seem a bit naive.

Economic Indicators Affecting ‘Made in USA’ Initiatives

| Indicator | Description | Impact on “Made in USA” |

|---|---|---|

| GDP Growth Rate | Measures the rate of economic expansion. | Higher growth generally correlates with increased demand for manufactured goods. |

| Unemployment Rate | Percentage of the labor force that is unemployed. | High unemployment can negatively impact domestic manufacturing, as it reduces consumer spending. |

| Inflation Rate | Rate of increase in the general price level of goods and services. | High inflation can reduce purchasing power and impact manufacturing costs. |

| Exchange Rates | Value of one currency relative to another. | Fluctuating exchange rates affect the competitiveness of US-made goods in international markets. |

| Consumer Confidence | Measure of consumer optimism about the economy. | Higher consumer confidence typically leads to increased demand for manufactured goods. |

Public Perception and Support for ‘Made in USA’

The “Made in USA” label holds significant cultural and economic weight. Public perception of this concept often hinges on factors beyond simple price comparisons. Consumers are increasingly aware of the ethical and environmental implications of their purchases, and the “Made in USA” label can serve as a signal of these values. This analysis delves into the public’s current perspective on supporting domestic manufacturing.Public perception of “Made in USA” is complex and multifaceted.

While there’s a general desire for supporting American businesses, this sentiment is not uniformly applied. A variety of factors, including price, perceived quality, and readily available alternatives, all contribute to the consumer’s decision-making process.

Consumer Perception of “Made in USA”

Consumer preferences for “Made in USA” products are influenced by a multitude of factors. The perceived quality and durability of American-made goods play a significant role. Some consumers may be willing to pay a premium for products they believe are built to last and crafted with higher standards. Conversely, the cost of American-made products can be a significant barrier, particularly for budget-conscious consumers.

A strong “Made in USA” marketing campaign can shift consumer perception, highlighting the benefits of supporting domestic production.

Successful “Made in USA” Campaigns

Numerous campaigns have attempted to raise awareness and bolster consumer support for American-made products. Successful campaigns often leverage patriotic themes and emphasize the benefits of supporting American jobs. For example, campaigns showcasing the craftsmanship and innovation of American manufacturers have resonated with consumers. A campaign by a specific furniture manufacturer that highlighted the use of sustainably harvested American hardwoods and the employment of local artisans resonated strongly with environmentally conscious consumers and those valuing quality.

The positive publicity surrounding these campaigns influenced purchasing decisions, demonstrating the potential of targeted marketing.

Role of Consumer Awareness

Consumer awareness of the “Made in USA” label is crucial. When consumers are informed about the origins of their purchases and the economic benefits of supporting domestic production, they’re more likely to prioritize “Made in USA” goods. Educational initiatives and transparent labeling are vital for building consumer awareness. For example, a national campaign highlighting the history and significance of American manufacturing can create a deeper understanding and appreciation of “Made in USA” products.

Demographic Differences in Support

Public support for “Made in USA” varies across demographics. Millennials and Gen Z, in particular, are increasingly interested in purchasing ethically sourced and sustainable products, which can influence their support for “Made in USA” goods. However, factors like income and access to affordable alternatives may affect the purchasing decisions of individuals across all demographics.

Influence of Media Portrayals

Media portrayals significantly impact public opinion on “Made in USA.” Positive media coverage of American manufacturers and their products can create a more favorable perception of “Made in USA” goods. Conversely, negative media portrayals of American manufacturing, especially those highlighting job losses or environmental concerns, can negatively impact public perception. For example, a documentary showcasing the environmental responsibility of an American-made energy company could shift consumer attitudes toward the brand.

Summary of Public Opinion Polls on “Made in USA”

| Poll Source | Date | Percentage Supporting “Made in USA” | Key Findings |

|---|---|---|---|

| National Consumer Survey | 2023 | 62% | Strong support among environmentally conscious consumers. |

| Pew Research Center | 2022 | 58% | Support varied significantly based on age group. |

| Gallup Poll | 2021 | 70% | Higher support among older generations. |

Note: Data is hypothetical and for illustrative purposes only. Actual poll data would need to be referenced from reputable sources.

Possible Solutions and Future Outlook

The challenges facing US manufacturers demand a multifaceted approach, moving beyond rhetoric and into concrete strategies. Innovation, strategic partnerships, and workforce development are crucial components in revitalizing American manufacturing. This requires a proactive and collaborative effort between government, industry, and academia to foster a supportive ecosystem for growth. A strong “Made in USA” future hinges on addressing these challenges head-on.A sustained commitment to innovation and technological advancements is paramount.

This includes significant investment in research and development, supporting emerging technologies like automation and advanced materials, and fostering a culture of entrepreneurship in the manufacturing sector. Success in these areas will be critical to boosting domestic production and maintaining competitiveness in the global market.

Potential Strategies to Overcome Challenges

Several strategies can help US manufacturers overcome the obstacles they face. These strategies encompass a wide range of approaches, from fostering innovation to supporting workforce development.

- Investing in Research and Development (R&D): Increased government funding for R&D in manufacturing technologies can lead to breakthroughs in efficiency, sustainability, and productivity. Examples include supporting the development of 3D printing techniques for customized parts, or exploring new materials with enhanced properties, thus reducing production costs and improving product quality.

- Enhancing Workforce Development and Training: The manufacturing sector requires a skilled workforce. Investing in vocational training programs and apprenticeships can equip workers with the necessary technical skills for modern manufacturing processes. This also includes addressing the needs of an aging workforce by upskilling current employees to prepare them for emerging technologies.

- Promoting Industry-Academia Partnerships: Collaboration between universities and companies can lead to the rapid transfer of knowledge and technological advancements. Joint research projects can lead to new product development and improve manufacturing processes. Examples include creating shared labs or facilitating internships for students to gain practical experience.

- Attracting and Retaining Talent: Competitive salaries, benefits packages, and opportunities for career advancement are crucial for attracting and retaining skilled workers in the manufacturing sector. Promoting a positive image of manufacturing jobs as fulfilling and high-paying careers can help overcome potential misconceptions.

- Leveraging Automation and Robotics: The integration of automation and robotics can increase productivity and efficiency in manufacturing. Training programs that prepare workers to operate and maintain automated systems are crucial to successfully incorporate these technologies.

Importance of Innovation and Technological Advancements, Made in usa is harder than trump thinks

Innovation and technological advancements are crucial for boosting domestic production and maintaining global competitiveness. These advancements allow for more efficient production, reduced costs, and the creation of higher-value products.

“Technological advancements are not just about replacing human labor; they are about enhancing human capabilities and creating new opportunities.”

Examples of successful technological advancements include the use of advanced materials, robotics, and automation in manufacturing processes. These technologies can enhance productivity, reduce costs, and improve product quality.

Successful Government-Industry-Academia Partnerships

Examples of successful partnerships between government, industry, and academia demonstrate the potential for collaboration in fostering innovation and growth. These collaborations often lead to the development of new technologies and products that are well-suited to the needs of the manufacturing sector.

- National Institutes of Standards and Technology (NIST): NIST collaborates with industries to develop standards and best practices for manufacturing processes. This facilitates the adoption of new technologies and fosters innovation across the sector.

- State-level initiatives: Many states have launched initiatives to support manufacturing, such as providing grants or tax incentives to companies that invest in new technologies. This fosters a supportive environment for growth and innovation.

Developing a Plan to Support US Manufacturing

Developing a comprehensive plan to support US manufacturing requires a systematic approach. This includes establishing clear goals, identifying key stakeholders, and creating a roadmap for implementation.

- Establish Clear Goals: Define specific, measurable, achievable, relevant, and time-bound (SMART) goals for the manufacturing sector, such as increasing domestic production of critical components or reducing manufacturing costs.

- Identify Key Stakeholders: Involve government agencies, industry representatives, and academic institutions in the planning process. This collaborative approach ensures a holistic understanding of the needs and challenges faced by the sector.

- Create a Roadmap for Implementation: Develop a detailed plan outlining specific actions, timelines, and resources required to achieve the identified goals. This plan should include strategies for workforce development, technology adoption, and industry-academia partnerships.

Ending Remarks

In conclusion, while the “Made in USA” ideal holds considerable appeal, the path to achieving this goal is proving more complex than anticipated. The intricate interplay of manufacturing challenges, economic factors, and public perception necessitates a multifaceted approach. Moving forward, a comprehensive strategy encompassing workforce development, technological innovation, and supportive government policies will be essential to fostering a robust and competitive US manufacturing sector.

Ultimately, overcoming these obstacles will require a commitment to innovation, collaboration, and a realistic understanding of the global landscape.