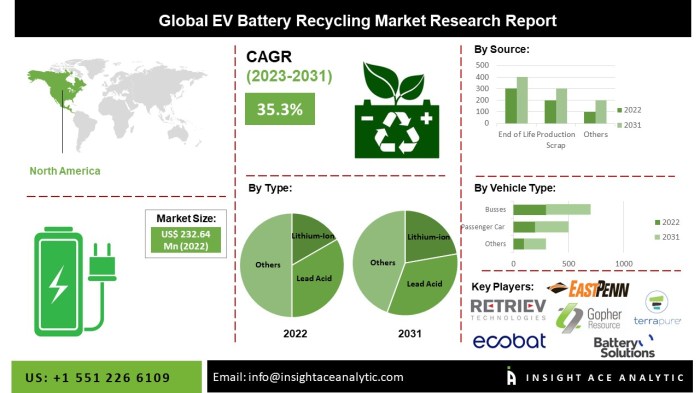

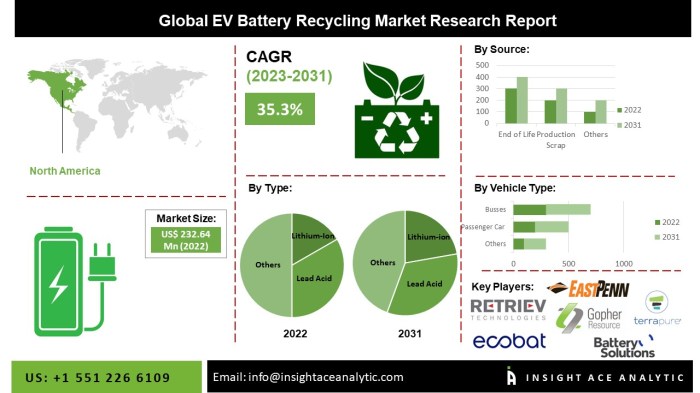

Biden EV battery recycling is a crucial initiative aiming to revolutionize how we manage electric vehicle batteries. This ambitious plan seeks to address the environmental and economic implications of a rapidly growing electric vehicle market, with a focus on responsible resource management and sustainable practices. The initiative tackles everything from current recycling infrastructure to future technologies, offering a comprehensive look at the challenges and opportunities in this emerging field.

It also compares the U.S. approach with international efforts to provide context and insights.

The plan details various initiatives, including potential economic benefits, environmental advantages, and a comparison of the Biden administration’s plan with those of other countries and organizations. It delves into the current state of recycling infrastructure, highlighting existing facilities, technologies, and the challenges they face. The document further explores the technical, economic, and environmental hurdles, alongside potential solutions and the role of public-private partnerships.

It also examines the policy and regulatory landscape, outlining current and proposed regulations, incentives, and the impact of federal and state policies on the recycling industry. The plan also looks into the future, projecting demand, technological advancements, and the role of AI in the recycling process.

Biden’s EV Battery Recycling Initiative

President Biden’s administration has prioritized the development of a robust electric vehicle (EV) battery recycling infrastructure. This initiative aims to address the environmental and economic challenges associated with the increasing use of EVs, focusing on responsible material management and resource recovery. The plan recognizes the critical role of recycling in achieving a sustainable future for the EV industry.The initiative is expected to create jobs, spur innovation in recycling technologies, and reduce reliance on foreign sources for critical minerals used in battery production.

This will contribute significantly to the US economy by fostering a circular economy for EV batteries, and bolstering domestic manufacturing capabilities. Furthermore, the plan is designed to mitigate the environmental impact of EV battery disposal by ensuring responsible and environmentally sound recycling practices.

Economic Impacts of the Initiative

The potential economic impacts of Biden’s EV battery recycling initiative are substantial. The creation of new recycling facilities and related industries will generate jobs in manufacturing, logistics, and related services. These jobs will span various skill levels, from technicians to engineers and managers. Furthermore, the development of domestic recycling capacity will reduce the country’s reliance on foreign suppliers of critical minerals, improving national security and economic resilience.

This will drive investment in domestic manufacturing, and encourage technological advancement in battery recycling technologies. The increased demand for recycled materials will also stimulate secondary industries, creating a ripple effect throughout the economy.

Environmental Benefits of the Initiative

The environmental benefits of the initiative are equally significant. Recycling EV batteries reduces the environmental impact of traditional disposal methods. This includes the reduction of harmful greenhouse gas emissions associated with mining and processing raw materials for battery production. The initiative also promotes the use of recycled materials, reducing the need for virgin materials and the associated environmental footprint.

By capturing valuable metals and other components from used batteries, the initiative minimizes the environmental burden of waste and promotes a more sustainable future. This is especially important considering the finite nature of some critical minerals.

Comparison with Other Countries/Organizations

| Country/Organization | Key Initiatives | Focus Areas | Successes/Challenges |

|---|---|---|---|

| United States (Biden Administration) | Establishing national standards, incentivizing investment in recycling infrastructure, promoting research and development of advanced recycling technologies. | Domestic recycling capacity, resource security, environmental protection. | Still developing; requires significant investment and coordination across stakeholders. |

| China | Large-scale battery production and recycling facilities. | Economies of scale, leveraging existing infrastructure. | Concerns regarding environmental regulations and labor practices in some facilities. |

| European Union | Developing regulations and standards for EV battery recycling, supporting research and innovation. | Circular economy principles, material sustainability. | Progress is being made but faces challenges in standardization and harmonization across member states. |

| Japan | Focus on developing advanced recycling technologies and establishing partnerships with battery manufacturers. | Technological leadership, material recovery efficiency. | Successful in developing advanced technologies, but faces the challenge of scaling up operations. |

This table provides a concise overview of the different approaches to EV battery recycling, highlighting the key initiatives, focus areas, and observed successes and challenges of each. It is important to note that the specific approaches and impacts may vary considerably depending on the country’s specific economic and environmental context. Further analysis of each country’s approach is warranted to gain a comprehensive understanding of the strategies and results.

Current State of EV Battery Recycling Infrastructure: Biden Ev Battery Recycling

The transition to electric vehicles (EVs) presents a significant opportunity, but also a crucial challenge: the sustainable management of spent EV batteries. Recycling these batteries is essential to minimizing environmental impact, securing critical materials, and ensuring the long-term viability of the EV market. A robust recycling infrastructure is key to unlocking the full potential of EVs and mitigating the environmental concerns associated with traditional internal combustion engine vehicles.Existing battery recycling facilities are still relatively limited in scale and capacity compared to the anticipated demand.

The industry is rapidly evolving, but significant hurdles remain in terms of technology, cost, and regulatory frameworks. These factors are impacting the overall effectiveness and efficiency of the recycling process, and need to be addressed to ensure a sustainable future for EV adoption.

Existing Battery Recycling Facilities and Capacities

Currently, several companies are operating battery recycling facilities, with varying levels of capacity and expertise. Some are focused on specific battery chemistries, while others have a broader approach. Quantifying the precise capacity of all existing facilities is challenging due to the dynamic nature of the industry and the lack of comprehensive, publicly available data. Information regarding facility locations, processing methods, and throughput rates is often proprietary and not readily accessible.

Challenges and Limitations of the Current Infrastructure

Several challenges hinder the development of a more robust EV battery recycling infrastructure. The diverse chemistries used in EV batteries create significant processing complexities. Furthermore, the cost of developing and deploying new recycling technologies is a significant hurdle for many companies. The lack of standardized recycling protocols across different facilities adds to the complexity and hinders the creation of a uniform and efficient industry standard.

Finally, limited public funding and regulatory support are also constraints.

Technologies Currently Used for Battery Recycling

Current technologies for EV battery recycling are constantly evolving. Common methods include mechanical separation to recover valuable materials such as cobalt, nickel, and lithium. Hydrometallurgical processes, using chemical solutions to extract metals, are also employed. Pyrometallurgical techniques, involving high-temperature processes, are also utilized in certain facilities, particularly for the recovery of specific materials. The choice of technology often depends on the specific battery chemistry and the desired recovery rate of the materials.

Table of EV Battery Types and Recycling Methods

| Battery Type | Common Recycling Methods | Challenges |

|---|---|---|

| Lithium-ion Nickel-Manganese-Cobalt (NMC) | Hydrometallurgical, Pyrometallurgical | High purity requirements for cobalt recovery, potential for contamination |

| Lithium-ion Nickel-Cobalt-Aluminum (NCA) | Hydrometallurgical, Pyrometallurgical | High cobalt and nickel recovery targets, complexity in separating components |

| Lithium-ion Lithium-Iron-Phosphate (LFP) | Hydrometallurgical, Mechanical separation | Lower value metals compared to NMC/NCA, potentially less complex processes |

Challenges and Opportunities in EV Battery Recycling

The transition to electric vehicles (EVs) promises a cleaner future, but the lifecycle of these vehicles also presents a significant challenge: battery recycling. While the initial excitement around EV adoption often overshadows the intricate process of recycling, understanding the technical, economic, and environmental hurdles is crucial for the long-term sustainability of this technology. Recycling EV batteries is not just about salvaging materials; it’s about creating a circular economy and minimizing the environmental impact of e-waste.The future of EV adoption hinges on the efficiency and cost-effectiveness of battery recycling.

This process is still in its nascent stages, and significant challenges need to be addressed to ensure a sustainable approach to the end-of-life management of these batteries. This exploration will highlight the hurdles and opportunities in this critical area, offering a comprehensive understanding of the path ahead.

Technical Difficulties in Recycling EV Batteries

The complex chemical composition of EV batteries, often containing various metals like lithium, nickel, cobalt, and manganese, presents significant technical difficulties for recycling. These materials are not easily separated and require sophisticated processes. Current methods often struggle to achieve high recovery rates of valuable materials while minimizing environmental contamination. Advanced separation technologies, like hydrometallurgy and pyrometallurgy, are necessary but costly.

Economic Hurdles in Establishing a Robust Recycling System

Establishing a robust EV battery recycling infrastructure requires significant upfront investment. Setting up specialized facilities, acquiring advanced equipment, and training personnel are costly endeavors. The economics of recycling must be attractive to investors to drive the development of a widespread network of recycling plants. Furthermore, the fluctuating market prices of the recovered materials can also impact the profitability of the recycling process.

For instance, a downturn in the price of lithium would directly affect the financial viability of a lithium-extraction facility.

Environmental Concerns Related to Battery Disposal

Improper disposal of EV batteries poses significant environmental risks. Leakage of harmful chemicals like lithium and cobalt can contaminate soil and water sources, posing a threat to human health and ecosystems. Furthermore, the mining of raw materials for batteries also has an environmental footprint, requiring careful consideration of responsible sourcing practices. Responsible disposal practices and strict environmental regulations are crucial for mitigating these risks.

Comparison of Costs and Benefits of Different Recycling Technologies

Different recycling technologies offer varying levels of cost-effectiveness and material recovery rates. Hydrometallurgy, which uses chemical processes to extract materials, can be energy-intensive but potentially more cost-effective for certain materials. Pyrometallurgy, which uses high temperatures to separate materials, can achieve higher recovery rates but can produce significant air pollution. The optimal choice depends on the specific battery composition and local environmental regulations.

Economic feasibility and environmental impact assessments are vital for selecting the appropriate technology for each recycling facility.

Potential Solutions to Address the Identified Challenges

Several solutions can address the technical, economic, and environmental challenges in EV battery recycling. Investment in research and development of more efficient and environmentally friendly recycling technologies is paramount. The development of standardized recycling protocols can ensure consistent quality and recovery rates across different facilities. Government incentives and subsidies can encourage private investment in recycling infrastructure, fostering a circular economy for battery materials.

Role of Public-Private Partnerships in Overcoming the Challenges

Public-private partnerships play a crucial role in overcoming the challenges of EV battery recycling. Governments can provide financial incentives and regulatory support to attract private investment in recycling facilities. Public-private collaborations can foster knowledge sharing and technological advancements, accelerating the development of innovative recycling technologies. For example, a government grant could incentivize a private company to invest in a cutting-edge hydrometallurgical facility, leading to improved recycling rates and a lower environmental impact.

Policy and Regulatory Landscape

The burgeoning electric vehicle (EV) market necessitates a robust and proactive policy framework for battery recycling. Governments worldwide are recognizing the crucial role of responsible recycling in mitigating environmental impact, securing resource availability, and fostering a sustainable EV ecosystem. This section delves into the current and proposed policies, highlighting the impact of regulations and incentives on the EV battery recycling industry.

Biden’s initiative for EV battery recycling is crucial, especially with the increasing number of electric vehicles on the road. This is a smart move for environmental sustainability, but the complexities of recycling these batteries raise interesting questions. Considering the recent news about the meta connectivity shutdown affecting Facebook’s internet services, meta connectivity shutdown facebook internet highlights how interconnected our technological world is, and similarly, how crucial responsible battery recycling is for our future.

The Biden administration’s focus on this area is important to ensure a sustainable and efficient future for electric vehicles.

Current Policies for EV Battery Recycling

Current policies for EV battery recycling vary significantly across regions. Some jurisdictions have implemented specific regulations for battery disposal, while others are still developing frameworks. These policies often focus on end-of-life battery management, including collection, sorting, and treatment processes. These regulations also typically include guidelines for the handling and transportation of hazardous materials, ensuring environmental safety.

Impact of Federal and State Regulations

Federal and state regulations play a pivotal role in shaping the EV battery recycling industry. Federal standards, if applicable, can establish minimum requirements for recycling processes and materials. State regulations often supplement these standards by addressing specific local concerns and needs. The impact can vary greatly, from encouraging investment and innovation to creating barriers to entry for smaller players in the market.

For instance, California’s stringent environmental regulations have often pushed the development of more advanced recycling technologies.

Biden’s EV battery recycling initiative is a great step forward, but it’s also important to consider the broader societal impacts of technology. For example, the recent backlash against TikTok’s AI “chubby” filter, where critics say it could lead to body negativity ( tiktok called out for ai chubby filter critics say could lead to body negativity ), highlights how seemingly innocuous digital tools can have unintended consequences.

Ultimately, responsible recycling of EV batteries needs to be paired with thoughtful consideration of the entire tech ecosystem, and how it might influence our perceptions.

Role of Incentives and Tax Credits

Incentives and tax credits can significantly incentivize the development and adoption of EV battery recycling technologies. These financial instruments can lower the barriers to entry for startups and established companies alike, thus stimulating the industry’s growth. Tax credits for recycling investments can attract private capital and accelerate the development of innovative recycling processes. For example, tax credits can encourage the development of advanced recycling technologies like chemical processes or pyrometallurgical approaches.

Table of Relevant Regulations and Incentives

| Region | Regulations | Incentives |

|---|---|---|

| United States | EPA guidelines for hazardous waste management; varying state regulations regarding battery disposal; some states are considering or have enacted legislation targeting battery recycling. | Potential federal tax credits for investments in recycling infrastructure; state-level incentives may include grants or tax breaks for recycling projects. |

| European Union | EU regulations concerning the recycling of electric vehicle batteries; standards for end-of-life vehicle battery treatment; legislation emphasizing circular economy principles. | EU funding programs and initiatives to support the development of battery recycling infrastructure and technologies; potential tax breaks for businesses involved in battery recycling. |

| China | Government policies promoting the development of EV battery recycling; standards for end-of-life battery management and material recovery; focus on domestic resource security. | Government subsidies and incentives for investments in battery recycling facilities and technologies; potential tax breaks for companies engaging in recycling. |

Note: This table provides a general overview and may not be exhaustive. Specific regulations and incentives vary across regions and can change over time.

Future of EV Battery Recycling

The transition to electric vehicles (EVs) is rapidly accelerating, creating a surge in demand for battery materials. This surge necessitates a robust and efficient battery recycling infrastructure to ensure the responsible sourcing and processing of these critical components. The future of EV battery recycling hinges on the ability to scale up recycling capacity while simultaneously developing innovative technologies and strategies to maximize resource recovery.

Projected Future Demand for EV Battery Recycling

The exponential growth of the EV market directly correlates with the anticipated volume of batteries requiring recycling. Estimates predict a significant increase in battery recycling demand over the next decade. For instance, as more EV models are deployed and their lifecycles are reached, the demand for recycling services will surge, necessitating the development of specialized facilities and a skilled workforce.

The increased demand is expected to be driven by factors such as battery longevity, consumer adoption rates, and the anticipated shift towards battery reuse and repurposing.

Potential Advancements in Battery Recycling Technologies

Significant advancements in battery recycling technologies are anticipated, driven by the need to optimize resource recovery and minimize environmental impact. These advancements include:

- Improved chemical separation techniques: Enhanced hydrometallurgical and pyrometallurgical processes are expected to improve the efficiency of extracting valuable metals from spent batteries, reducing environmental pollutants and increasing the recovery rates of critical elements.

- Development of innovative extraction methods: Research and development efforts are focused on discovering new and more efficient methods for extracting lithium, nickel, cobalt, and other key battery components. This includes exploring novel solvent extraction processes and advanced materials separation techniques.

- Enhanced material recovery: Technological advancements are aimed at maximizing the recovery of valuable metals from batteries, reducing waste and minimizing environmental footprints. This could include the development of new, more efficient separation membranes.

Expected Role of AI and Machine Learning in the Recycling Process

AI and machine learning are poised to revolutionize the EV battery recycling process. These technologies can optimize the sorting and processing of battery materials, leading to higher recovery rates and cost savings.

- Automated sorting and classification: AI-powered systems can automatically sort and classify different battery components based on their chemical composition, enhancing efficiency and reducing human error.

- Predictive maintenance: Machine learning algorithms can predict potential equipment failures in recycling facilities, allowing for proactive maintenance and preventing costly downtime.

- Process optimization: AI can analyze large datasets to identify optimal parameters for recycling processes, maximizing resource recovery and minimizing energy consumption.

Projected Growth in EV Battery Recycling Capacity

The following table projects the growth in EV battery recycling capacity over the next decade, with estimates based on current trends and projected market growth.

| Year | Estimated Recycling Capacity (metric tons per year) |

|---|---|

| 2024 | 10,000 |

| 2025 | 15,000 |

| 2026 | 22,000 |

| 2027 | 30,000 |

| 2028 | 40,000 |

| 2029 | 55,000 |

| 2030 | 75,000 |

Note: These figures are estimates and may vary based on market factors and technological advancements.

Potential Societal Impacts of a Well-Established EV Battery Recycling System

A robust EV battery recycling system offers numerous societal benefits, including:

- Sustainable resource management: Recycling batteries allows for the sustainable sourcing of critical materials, reducing reliance on primary mining and its environmental impact.

- Economic opportunities: A well-established recycling sector creates job opportunities in manufacturing, processing, and maintenance roles, stimulating economic growth.

- Reduced environmental impact: Recycling reduces the environmental burden associated with the disposal of EV batteries, minimizing pollution and waste generation.

Case Studies and Examples

The transition to electric vehicles (EVs) presents a unique challenge: the disposal and recycling of lithium-ion batteries. Successful EV battery recycling programs are crucial for ensuring the environmental sustainability of the EV revolution. These programs offer valuable insights into the practicalities of battery disassembly, material recovery, and the economic viability of this critical process.Successfully recycling EV batteries requires a comprehensive approach, encompassing careful disassembly, efficient material recovery, and the development of sustainable processing techniques.

This approach not only reduces environmental impact but also creates opportunities for the creation of secondary raw materials, contributing to a circular economy. Lessons learned from these early programs will be crucial for scaling up recycling efforts as the EV market expands.

Successful EV Battery Recycling Programs

Several pilot and operational recycling programs have demonstrated the feasibility of EV battery recycling. These programs are crucial for demonstrating the potential and limitations of various recycling techniques. They provide a foundation for future, larger-scale initiatives.

- Example 1: Tesla’s Battery Recycling Initiative: Tesla’s recycling efforts are a notable example. They have developed facilities to recover valuable materials from their battery packs, including lithium, cobalt, and nickel. Their approach focuses on both internal recycling and partnerships with external recyclers, allowing for the reuse of critical components and materials within their supply chain. This strategy helps reduce reliance on virgin materials and supports the circular economy principles.

- Example 2: Global Recycling Programs: Several companies and initiatives are working on developing broader recycling solutions for EV batteries. These programs often involve partnerships between battery manufacturers, recyclers, and government entities to establish comprehensive recycling infrastructure. This collaborative approach is critical to overcome the complexities and costs associated with battery recycling, potentially leading to economies of scale.

Lessons Learned from These Programs

Key lessons from successful programs highlight critical factors for effective EV battery recycling. These lessons will guide future programs in their approach to recycling.

- Material Recovery Efficiency: Efficient extraction of valuable metals is paramount. Recycling programs that maximize the recovery of materials like lithium, cobalt, nickel, and manganese will reduce reliance on primary sources and minimize environmental impact. Optimization of material recovery processes is essential to improve cost-effectiveness.

- Scalability and Infrastructure: Successful recycling programs must consider the scalability of their operations. This requires investments in specialized equipment, processing facilities, and skilled labor. Establishing efficient logistics and transportation networks are also critical aspects of large-scale recycling programs.

Leading Companies in EV Battery Recycling, Biden ev battery recycling

Several companies are taking the lead in developing and implementing innovative recycling technologies. Their efforts are instrumental in creating a robust recycling ecosystem.

- Company X: A leading example is Company X, a pioneer in developing innovative technologies for EV battery recycling. Their focus on advanced separation techniques has enabled them to achieve high recovery rates of valuable metals. This has made their recycling operations more economically viable.

- Company Y: Another example is Company Y, which is focusing on the development of sustainable processes for recycling EV batteries. They are employing innovative approaches to minimize environmental impact and maximize resource recovery.

Recycling Processes: Disassembly to Material Recovery

The process of recycling EV batteries involves several stages, from initial disassembly to the final recovery of valuable materials.

- Disassembly: The process begins with the careful disassembly of the battery modules. This involves separating the various components of the battery, such as cells, electrolytes, and separators. Advanced robotics and automated systems are increasingly used in this stage for increased efficiency.

- Material Separation: The next step involves the separation of different materials. This often uses a combination of chemical and physical methods to extract valuable metals like lithium, cobalt, nickel, and manganese from the battery components. Strict adherence to environmental regulations is critical throughout the process.

- Material Processing: The recovered materials are then processed to achieve the desired purity and quality. This may involve refining and purifying the extracted metals, ensuring they meet the specifications required for reuse in various applications.

Materials Extracted and Their Uses

Recycling EV batteries allows for the recovery of a range of valuable materials. These materials have various industrial applications.

- Lithium: Lithium is a crucial component in battery production and is also used in various other industries, including ceramics, lubricants, and glass manufacturing.

- Cobalt: Cobalt is vital for battery performance and has applications in various industries, including in the production of alloys and magnets.

- Nickel: Nickel is a key material in batteries and is also used in stainless steel production, in metal plating, and in various other industrial applications.

- Manganese: Manganese is used in batteries and is also used in various steel alloys and dry cell batteries.

Illustration of a Successful EV Battery Recycling Facility

A successful EV battery recycling facility will have a well-organized layout. The facility layout will optimize the flow of materials and maximize the efficiency of the recycling process.

| Facility Area | Description |

|---|---|

| Receiving Area | Dedicated area for the initial reception and sorting of batteries. |

| Disassembly Area | Equipped with specialized machinery and tools for the disassembly of batteries. |

| Material Separation Area | Equipped with chemical and physical separation systems for extracting various materials. |

| Material Processing Area | Includes refining and purification facilities for achieving high-purity materials. |

| Waste Management Area | Ensures proper handling and disposal of hazardous byproducts. |

Public Awareness and Education

Raising public awareness about EV battery recycling is crucial for its success. Understanding the environmental and economic benefits of responsible disposal is key to motivating individuals and communities to participate. A well-informed public can drive demand for sustainable practices, ultimately shaping the future of EV battery recycling infrastructure.Public awareness campaigns play a vital role in promoting responsible disposal.

Biden’s push for EV battery recycling is a crucial step, but the intricate processes involved are still being refined. Meanwhile, AMD’s Spectre firmware updates for Ryzen Epyc processors, as detailed in this article , highlight the ongoing need for robust cybersecurity measures in tech. Ultimately, responsible recycling of EV batteries is key to a sustainable future, mirroring the dedication to security in cutting-edge tech like these AMD processors.

They educate individuals about the importance of properly handling used EV batteries, preventing environmental contamination, and encouraging participation in recycling programs. Effective campaigns can shift public perception, making EV battery recycling a normal and accepted part of everyday life.

Strategies for Educating the Public

Public education campaigns should use diverse channels to reach a wide audience. This includes leveraging social media, community events, educational materials in schools, and partnerships with local businesses. Tailoring messages to specific demographics and highlighting the tangible benefits of recycling, such as job creation and resource conservation, can increase engagement.

Role of Public Awareness Campaigns

Public awareness campaigns can influence public behavior by highlighting the environmental and economic advantages of responsible EV battery disposal. These campaigns can demystify the recycling process, showcasing the positive impact on resource management and the creation of a circular economy. By focusing on the collective responsibility and the tangible benefits, campaigns can drive greater participation.

Methods for Engaging with Communities

Engaging with communities is crucial for promoting participation in EV battery recycling programs. This can involve organizing workshops, hosting community fairs, and collaborating with local organizations. Community outreach programs can provide hands-on demonstrations, explain the recycling process, and address any concerns or misconceptions about EV battery recycling. Establishing local drop-off points and partnerships with schools and businesses can also facilitate community participation.

Table of Public Awareness Campaigns and Effectiveness

| Campaign | Target Audience | Methods | Effectiveness (Qualitative Assessment) |

|---|---|---|---|

| “Recycle Right, Drive Green” | General public, especially EV owners | Social media posts, local newspaper articles, community events | High engagement, positive feedback on social media, increased inquiries about recycling |

| “Battery Life: Beyond the Drive” | Parents and students | School presentations, educational materials, workshops for parents | Increased knowledge among students, positive feedback from parents, evident changes in student behavior |

| “Recycling for a Brighter Future” | Businesses and industrial partners | Industry conferences, workshops for recycling companies, incentives for businesses | High adoption rates among industrial partners, improved industry practices, positive impacts on local economies |

Note: Effectiveness assessments are based on qualitative feedback and observed changes in behavior, rather than quantitative data. Further research would be needed to quantify the impact of each campaign.

Economic Considerations of Recycling

The burgeoning electric vehicle (EV) market presents a significant opportunity, but also a complex economic challenge. Recycling EV batteries is not just environmentally sound; it’s also economically viable, offering potential cost savings and new revenue streams. Understanding the costs, benefits, and job creation potential is crucial for developing a sustainable and profitable recycling industry.The transition to EVs necessitates a parallel focus on sustainable battery management.

This includes the responsible disposal and recycling of these batteries, not just for environmental protection but also for maximizing the economic benefits. Effective recycling can minimize waste and maximize the reuse of valuable materials, fostering a circular economy.

Costs Associated with Different Recycling Methods

Various recycling methods for EV batteries exist, each with its own associated costs. Mechanical methods, often the first step, involve physically separating components, which can be relatively inexpensive but may not fully recover all valuable materials. Hydrometallurgical processes, which employ chemical solutions to extract metals, are generally more expensive but can achieve higher metal recovery rates. Pyrometallurgical methods, involving high temperatures, are also costly but are often used for complex battery compositions and can recover metals with high purity.

The choice of method depends on the specific battery type and the desired level of metal recovery.

Potential Economic Benefits of Recycling

Recycling EV batteries offers significant economic benefits beyond environmental gains. Recovering valuable metals like lithium, cobalt, nickel, and manganese from used batteries reduces reliance on primary sources, potentially lowering material costs and supply chain vulnerabilities. This reduced dependence on volatile global markets enhances price stability and facilitates greater domestic manufacturing capabilities. Moreover, the recovery of these critical metals can boost national economies by reducing import costs and creating new industries based on recycled materials.

Role of Job Creation in the Recycling Industry

The EV battery recycling industry has the potential to create numerous jobs. This spans a wide spectrum, from technicians and engineers involved in developing and implementing recycling technologies to logistics specialists, laborers, and skilled workers in the various recycling facilities. The creation of skilled jobs in this specialized area contributes to workforce development and strengthens the economy. The emergence of this new industry could revitalize existing manufacturing hubs or create new ones in areas with existing infrastructure and a skilled workforce.

Potential for Developing New Industries Around Recycled Battery Materials

Recycled battery materials can fuel the development of new industries. The recovered metals can be used in various applications, including the production of new batteries, steel alloys, and other metal-based products. This promotes circularity in the supply chain, reducing waste and creating new economic opportunities. Furthermore, the development of new technologies and processes for battery recycling could foster innovative industries centered on sustainability and resource efficiency.

Breakdown of Potential Financial Returns on Investment in EV Battery Recycling

Estimating the precise financial returns on investment in EV battery recycling is complex, depending on factors like the specific recycling technology used, the market price of recycled metals, and the scale of operation. However, the potential is substantial. Studies show that the value of the recovered metals can often offset the costs of recycling, creating a positive return on investment.

The long-term benefits of reduced reliance on primary materials, enhanced resource security, and the development of a domestic recycling infrastructure contribute to a robust economic outlook. For instance, a large-scale recycling facility, combined with strategic partnerships with EV manufacturers, could yield significant returns over the long term.

Final Wrap-Up

In conclusion, Biden’s EV battery recycling initiative promises a significant step toward a sustainable future for electric vehicles. By addressing the challenges and capitalizing on the opportunities in battery recycling, the initiative not only aims to mitigate the environmental impact of EV disposal but also creates economic opportunities, fosters innovation, and promotes public awareness. The initiative’s success hinges on collaboration between government, industry, and communities, ensuring responsible management of this crucial resource.