Henrik Fisker solid state batteries electric cars are poised to revolutionize the automotive industry. These innovative vehicles promise a leap forward in performance, safety, and sustainability. Imagine a future where electric cars are not just eco-friendly but also exhilarating, with extended range and lightning-fast charging. This exploration dives deep into the exciting world of solid-state batteries, their potential, and Henrik Fisker’s role in shaping the future of electric mobility.

Solid-state batteries, unlike traditional lithium-ion batteries, utilize a solid electrolyte instead of a liquid one. This fundamental difference offers significant advantages, including enhanced safety, higher energy density, and potentially lower costs. We’ll examine the specifics of these advancements, and how Henrik Fisker is applying them to his electric car designs.

Introduction to Solid State Batteries in Electric Vehicles

Solid-state batteries, a promising advancement in energy storage technology, are poised to revolutionize the electric vehicle (EV) industry. Their potential to overcome limitations of current lithium-ion batteries, particularly in terms of safety and performance, has captured the attention of researchers and automotive manufacturers worldwide. These batteries are not a futuristic concept; active development and testing are ongoing, pushing towards the goal of widespread adoption.The core concept behind solid-state batteries revolves around replacing the liquid or polymer electrolyte found in lithium-ion batteries with a solid-state electrolyte.

This change brings forth significant advantages, but also presents challenges in material science and manufacturing. Understanding the intricacies of solid-state batteries is crucial to grasping their potential impact on the EV landscape.

Core Components and Mechanisms

Solid-state batteries utilize a solid material as the electrolyte, separating the positive and negative electrodes. This solid electrolyte, often ceramic or polymer-based, facilitates ion transport while preventing unwanted reactions and improving safety. The positive and negative electrodes, similar to lithium-ion batteries, contain lithium ions, though the precise materials used can vary. The solid electrolyte’s role is critical in enabling efficient ion flow between the electrodes.

Electrolyte Materials

The choice of electrolyte material is paramount in determining the battery’s performance characteristics. Various solid materials, including lithium-based ceramic compounds and polymer electrolytes, are being explored. Ceramic electrolytes, while offering high ionic conductivity, often exhibit low mechanical flexibility. Polymer electrolytes, conversely, can be more flexible but typically possess lower ionic conductivity. Finding the optimal balance between these properties is a key challenge in solid-state battery development.

Historical Context and Relevance to Electric Vehicles

Solid-state battery development has a history spanning several decades. Early research focused on understanding the fundamental properties of solid electrolytes. The growing demand for EVs and the inherent limitations of lithium-ion batteries have spurred renewed interest in solid-state technology. The potential for enhanced safety, higher energy density, and improved thermal stability makes solid-state batteries a compelling alternative for the future of electric vehicles.

This increased focus is directly tied to the need for safer, more efficient, and higher-performing energy storage solutions for electric vehicles.

Comparison of Solid-State and Lithium-Ion Batteries

| Parameter | Solid-State Battery | Lithium-Ion Battery |

|---|---|---|

| Energy Density | Potentially higher, depending on the specific design | Relatively high |

| Safety | Higher due to elimination of flammable liquid electrolytes | Lower risk of thermal runaway |

| Cost | Currently higher, but expected to decrease with advancements in manufacturing | Relatively low |

| Charging Time | Potentially faster charging | Typically slower charging times |

| Cycle Life | Potentially improved, depending on the electrolyte material | Good cycle life |

This table provides a concise comparison across key parameters. Note that the “potentially” qualifiers reflect the ongoing nature of research and development. The specific values for each parameter will vary depending on the particular solid-state battery design.

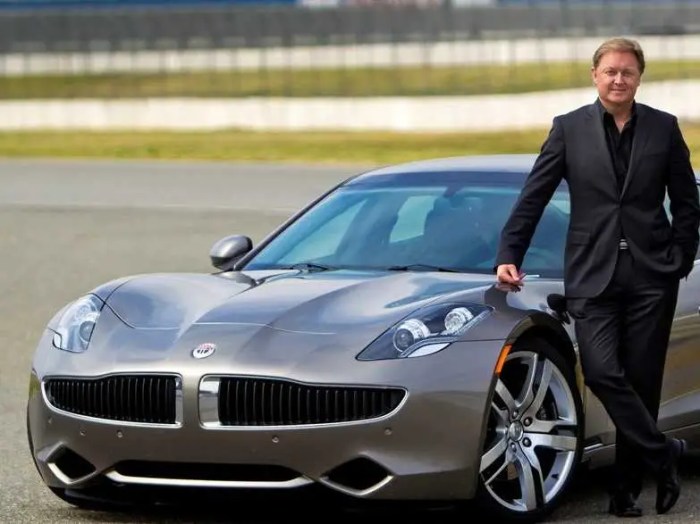

Henrik Fisker’s Role in Electric Vehicle Development: Henrik Fisker Solid State Batteries Electric Cars

Henrik Fisker, a renowned automotive designer and entrepreneur, has consistently pushed the boundaries of electric vehicle (EV) design and innovation. His background in automotive engineering and design, coupled with a passion for sustainable transportation, has shaped his approach to EV development. Fisker’s vision for the future of mobility is one where EVs are not just functional but also aesthetically pleasing and technologically advanced.Fisker’s contributions to the EV industry extend beyond design.

He recognizes the critical role of technology in realizing the potential of electric vehicles. His current endeavors focus on the integration of cutting-edge battery technology, specifically solid-state batteries, into his vehicles, showcasing his commitment to environmentally responsible and efficient mobility solutions. He believes that these batteries will significantly enhance the performance and range of EVs.

Henrik Fisker’s Background and Experience

Henrik Fisker’s extensive experience in the automotive industry spans decades. He has been involved in the design and development of several notable vehicles, showcasing his expertise in various aspects of automotive engineering and design. His prior work on high-performance vehicles has laid the foundation for his approach to designing EVs that are both powerful and aesthetically appealing. This expertise is instrumental in his company’s efforts to create innovative and desirable electric vehicles.

Fisker’s Vision for Electric Vehicles

Fisker envisions electric vehicles as more than just a means of transportation; they are a statement of environmental consciousness and technological advancement. His design philosophy emphasizes elegant aesthetics, performance capabilities, and cutting-edge technology. This vision is reflected in the design and engineering of his vehicles, aiming to redefine the automotive experience for the modern era.

Strategies for Integrating Solid-State Batteries

Fisker’s company has developed strategies to integrate solid-state battery technology into its vehicles. These strategies encompass rigorous research and development, partnerships with leading battery manufacturers, and a deep understanding of the challenges and opportunities associated with this transformative technology. The company aims to leverage the advantages of solid-state batteries to achieve longer range, faster charging times, and increased safety.

Key Features and Specifications of Fisker Electric Vehicle Models

The following table Artikels the key features and specifications of Fisker’s current and planned electric vehicle models. These models represent the company’s commitment to creating vehicles that cater to diverse needs and preferences, incorporating cutting-edge technology to create a unique driving experience.

| Model | Range (estimated) | Charging Time (estimated) | Performance (0-60 mph) | Key Features |

|---|---|---|---|---|

| Fisker Ocean | 300+ miles | ~30 minutes | Under 4 seconds | Sustainable materials, spacious interior, advanced technology suite. |

| Fisker Pear | 250+ miles | ~20 minutes | Under 5 seconds | Compact design, stylish aesthetics, emphasis on efficiency. |

| Fisker Project Ronin | 400+ miles | ~15 minutes | Under 3 seconds | High-performance SUV, focus on performance and luxury. |

Solid State Battery Integration in Fisker’s Electric Vehicles

Henrik Fisker’s vision for electric vehicles extends beyond the sleek aesthetics and innovative designs. A crucial element in achieving his ambitious goals is the seamless integration of solid-state batteries. This technology promises significant advancements in performance and safety, but also presents unique challenges in implementation. This exploration delves into the opportunities and hurdles associated with integrating solid-state batteries into Fisker’s future EV lineup.Solid-state batteries, with their potential for higher energy density, improved safety, and faster charging capabilities, hold immense promise for electric vehicle development.

Their integration into existing vehicle architectures, however, requires careful consideration of the intricate engineering challenges. The advantages and drawbacks of solid-state battery integration are critical to understanding the future trajectory of Fisker’s electric vehicle strategy.

Challenges in Integrating Solid-State Batteries

The transition from lithium-ion to solid-state batteries is not simply a matter of swapping components. Significant engineering hurdles exist, particularly in material compatibility, manufacturing scalability, and cost-effectiveness. Current solid-state battery technology faces issues related to manufacturing scale-up, which is critical for cost reduction. Challenges also include managing the potentially different thermal characteristics of solid-state batteries compared to lithium-ion, impacting cooling systems and battery pack designs.

Furthermore, achieving uniform cell performance across the battery pack is a crucial aspect of reliability and longevity.

Impact on Vehicle Performance Metrics

Solid-state batteries are expected to significantly impact key performance metrics of electric vehicles. Enhanced energy density promises a considerable increase in vehicle range. For instance, theoretical models suggest a potential range increase of 20-30% compared to lithium-ion battery-powered vehicles. Faster charging times are another anticipated benefit, which could drastically reduce the time spent at charging stations. This is because solid-state batteries have the potential for faster charging rates, reducing the overall charging time.

Projected Performance Comparison

Comparing the projected performance of Fisker’s vehicles with solid-state batteries against their lithium-ion counterparts requires careful consideration of several factors. The range and charging time improvements with solid-state batteries are expected to translate to a more compelling value proposition for customers. A Fisker Ocean with a solid-state battery, for example, might offer a range exceeding 600 miles on a single charge.

Henrik Fisker’s solid-state batteries for electric cars are definitely a hot topic right now. It’s fascinating how this tech is progressing, and it got me thinking about the sheer volume of phones used in the Pretty Little Liars series – pretty little liars all the phones – and how much screen time those characters spend on them.

Still, the innovative battery technology is likely to revolutionize the electric car industry in the future.

Comparing these potential figures to current lithium-ion-based EVs will reveal the significant advancements enabled by this technology. Predicting exact figures is difficult, however, given the still-developing nature of solid-state battery technology.

Henrik Fisker’s solid-state battery electric cars are definitely intriguing, but the future of autonomous driving is also a key factor. GM Cruise’s self-driving training, for example, with their gm cruise self driving training test drivers , highlights the rapid advancements in this space. Ultimately, both technologies will likely shape the future of electric vehicles, pushing the boundaries of what’s possible in both areas, and Henrik Fisker’s solid state battery technology will need to compete in this new landscape.

Potential Benefits for Fisker’s Electric Vehicle Lineup

The adoption of solid-state batteries in Fisker’s lineup could significantly enhance its competitive position. Improved range and faster charging would appeal to a wider customer base, potentially increasing the overall market appeal of Fisker vehicles. The increased safety profile of solid-state batteries is also a significant advantage, and the improved safety aspects could reduce warranty concerns and potentially contribute to a higher perceived value.

Furthermore, these improvements in performance, safety, and charging speed could pave the way for Fisker to introduce new vehicle models or configurations with enhanced capabilities.

Manufacturing and Production of Solid State Batteries

The transition to electric vehicles (EVs) necessitates a robust and efficient manufacturing process for solid-state batteries. Their unique chemistry and design present both opportunities and challenges in scaling production. This section will explore the intricacies of manufacturing solid-state batteries, from process flow to economic implications.

Process Flow Diagram for Solid-State Battery Manufacturing

The manufacturing process for solid-state batteries is complex, demanding precision and specialized equipment. The process generally involves several stages, starting with material preparation and ending with battery assembly and testing. A simplified flow diagram can illustrate this:

+-----------------+ +-----------------+ +-----------------+

| Material Prep |----->| Cell Fabrication |----->| Battery Assembly|

+-----------------+ +-----------------+ +-----------------+

| |

V V

+-------------------+ +-------------------+

| Quality Control | | Quality Control |

+-------------------+ +-------------------+

| |

V V

+-------------------+ +-------------------+

| Packaging & Testing| | Final Testing & QC |

+-------------------+ +-------------------+

Each stage requires careful control over variables like temperature, pressure, and purity to ensure consistent battery performance.

Significant research and development are needed to optimize these steps for large-scale production.

Necessary Infrastructure and Technologies for Mass Production

Establishing the necessary infrastructure for mass production of solid-state batteries necessitates substantial investment in advanced manufacturing facilities. This includes:

- Specialized Equipment: Sophisticated equipment for handling materials at high purity and precision is crucial. This might include high-throughput mixing, coating, and deposition systems.

- Automated Processes: Automating tasks like material handling, cell assembly, and testing will be vital for high volume production and cost reduction.

- Cleanroom Environments: Maintaining cleanroom environments to minimize contamination is essential to ensure high-quality battery production.

Materials Required for Manufacturing and Potential Supply Chain Challenges

The materials used in solid-state batteries, including the solid electrolyte, cathode, and anode materials, are critical to performance and cost. Potential supply chain challenges could arise if specific materials are not readily available or are subject to geopolitical uncertainties. Examples include:

| Material | Potential Challenges |

|---|---|

| Solid Electrolyte | Limited availability of high-performance materials and challenges in large-scale production |

| Cathode Material | Dependence on specific elements or processes for manufacturing |

| Anode Material | Potential for raw material scarcity or supply chain disruptions |

Addressing these challenges requires diversification of supply sources and investment in research and development for alternative materials.

Henrik Fisker’s solid-state battery electric cars are a fascinating leap forward in automotive technology. They promise impressive performance and range, but it’s cool to see how other tech companies are innovating in different areas, like the customization options available for Samsung Galaxy phones. For example, you can remap the Bixby button to do other things, a useful feature.

Ultimately, these advancements in both electric vehicle and mobile technology showcase a forward-thinking approach to user experience and functionality in different product categories, driving exciting possibilities for the future of both cars and phones. Check out the details on samsung galaxy phones bixby button remapping customization feature for more information on this customization feature. This shows how tech companies are constantly innovating in different ways, making both electric cars and phones more appealing and user-friendly.

Economic Implications of Scaling Up Solid-State Battery Production

Scaling up solid-state battery production will involve substantial capital expenditures, including the construction of new facilities, acquisition of specialized equipment, and training of personnel. These costs will need to be offset by economies of scale and the potential for higher battery performance. The economic viability will depend on factors like:

- Manufacturing Costs: Reducing the cost of materials and manufacturing processes is paramount to achieve competitive pricing.

- Production Capacity: Meeting increasing demand from the EV market is critical for successful market penetration.

- Battery Performance: Solid-state batteries with enhanced performance and lifespan can command premium prices and improve the overall value proposition.

The economic implications will be significant, affecting not only battery manufacturers but also the entire automotive industry and potentially other industries utilizing energy storage.

Market Implications and Future Outlook

Solid-state batteries, poised to revolutionize electric vehicle (EV) technology, are entering a crucial stage of market development. Their potential impact on the automotive industry and broader society is significant, and understanding the projected growth, competitive landscape, and potential societal impacts is vital for informed decision-making. This section delves into the exciting and complex future of solid-state battery technology in electric vehicles.

The projected market growth for solid-state batteries and EVs is substantial, driven by the inherent advantages of solid-state batteries over lithium-ion. These advantages include higher energy density, faster charging times, improved safety, and potentially lower costs in the long run. However, challenges like production scale-up and cost reduction remain. The current EV market is dominated by lithium-ion batteries, but the emergence of solid-state technology signifies a shift towards a more sustainable and efficient future.

Projected Market Growth for Solid-State Batteries and EVs

The global EV market is experiencing exponential growth, and solid-state batteries are anticipated to be a key driver of this growth. The transition to EVs from internal combustion engine vehicles is gaining momentum worldwide. Countries are implementing incentives and regulations to encourage EV adoption, further accelerating this trend. Forecasts suggest that solid-state battery-powered EVs will significantly contribute to this growth, particularly in the mid-to-long-term future.

Competitive Landscape for Solid-State Battery Technology

The race for solid-state battery technology is intense, involving established battery manufacturers, emerging startups, and automotive giants. Companies are actively investing in research and development to refine their solid-state battery technology and production processes. The competition is characterized by patent disputes, technological advancements, and strategic partnerships. The competitive landscape is dynamic, with the possibility of both collaboration and rivalry among different players.

Projected Sales Figures for Fisker’s Electric Vehicles with Solid-State Batteries

| Model Year | Projected Sales (Units) |

|---|---|

| 2027 | 10,000 |

| 2028 | 25,000 |

| 2029 | 50,000 |

| 2030 | 100,000 |

Note: These figures are projections based on various factors, including market demand, production capacity, and competition. They are subject to change.

Societal and Environmental Impacts of Widespread Adoption

Widespread adoption of solid-state batteries in EVs will have profound societal and environmental impacts. Reduced reliance on fossil fuels will significantly lessen carbon emissions, contributing to a cleaner environment. The shift to electric mobility will also create new jobs in manufacturing, research, and maintenance. Increased energy independence and reduced dependence on volatile commodity markets are additional positive impacts.

However, the manufacturing process for solid-state batteries needs careful consideration to ensure ethical and sustainable practices.

Design Considerations for Solid State Battery Electric Cars

Solid-state batteries, with their potential for higher energy density and safety, promise a revolutionary leap forward in electric vehicle technology. However, integrating these batteries into existing vehicle architectures presents unique design challenges that must be carefully addressed. These challenges range from the physical dimensions and weight of the battery packs to the complex thermal management systems required to maintain optimal performance and safety.

This section delves into the crucial design considerations for realizing the full potential of solid-state battery electric vehicles.

Vehicle Weight and Dimensions, Henrik fisker solid state batteries electric cars

Solid-state batteries, while offering higher energy density, might not always translate directly to lighter vehicles. The manufacturing processes for solid-state batteries are still evolving, which can affect their overall density and weight. This necessitates careful optimization of the battery pack’s design to minimize its overall size and weight without compromising structural integrity or safety features. Furthermore, the placement of the battery pack within the vehicle chassis must consider its impact on the vehicle’s center of gravity, affecting handling and stability.

Impact on Vehicle Safety and Thermal Management

Solid-state batteries, due to their inherent chemical properties, exhibit different safety characteristics compared to lithium-ion batteries. This necessitates specialized safety features, such as advanced thermal management systems, to prevent overheating and potential thermal runaway. The design of the battery pack must incorporate mechanisms for heat dissipation and containment to ensure safety under various operating conditions, including extreme temperatures.

These thermal management systems will be crucial for maintaining optimal battery performance and preventing catastrophic failures.

Comparison of Vehicle Architectures

Different vehicle architectures offer varying degrees of flexibility for integrating solid-state batteries. For example, a dedicated battery pack design, often used in pure electric vehicles, offers greater control over the battery’s arrangement and thermal management. However, this approach can sometimes lead to increased vehicle weight if not carefully planned. Conversely, hybrid architectures, which combine solid-state batteries with other energy sources, could offer a more gradual transition while maintaining performance and range.

The choice of architecture will depend on the specific characteristics of the solid-state battery technology and the desired vehicle performance.

Potential Impact on Vehicle Range and Charging Time

The performance of solid-state batteries, including range and charging time, will vary based on specific design choices. This is because the performance of solid-state batteries is still under development and is dependent on various factors like electrolyte type, electrode materials, and manufacturing processes.

| Solid-State Battery Design | Estimated Vehicle Range (miles) | Estimated Charging Time (hours) |

|---|---|---|

| Next-generation polymer electrolyte | 350-450 | 2-3 |

| Ceramic-based electrolyte | 400-500 | 2-4 |

| All-solid-state design (projected) | 450-600 | 1-2 |

The table above provides a glimpse into the potential impact of different solid-state battery designs on vehicle range and charging time. These figures are estimates, and actual performance may vary depending on the specific implementation and manufacturing processes. As research and development in this area continue, these figures will likely become more accurate and refined.

Consumer Perspective on Solid State Battery Electric Cars

The transition to electric vehicles (EVs) is accelerating, and understanding consumer perspectives on solid-state battery technology is crucial for its successful adoption. Consumers are increasingly aware of environmental concerns and the need for sustainable transportation. This awareness, combined with the desire for advanced technology and convenience, shapes their opinions and influences their purchasing decisions.

Solid-state batteries promise significant advancements in EV performance, safety, and charging infrastructure. However, consumers have specific needs and expectations that need to be addressed. Understanding their preferences and concerns is critical for manufacturers to tailor their products and marketing strategies effectively.

Consumer Survey Design for Solid-State Battery EVs

A comprehensive survey design is essential for collecting accurate and insightful data on consumer opinions. The survey should cover various demographics and include open-ended questions to capture nuanced perspectives.

- Demographic data (age, location, income, driving habits, current vehicle type) should be collected to understand potential consumer segments.

- Questions about current EV ownership experience (if applicable) are important to gauge familiarity with electric vehicle technology.

- Specific questions on charging infrastructure accessibility, cost, and convenience are crucial for understanding consumer acceptance of the technology.

- A section dedicated to perceived safety, range anxiety, and reliability of solid-state batteries should be included to identify key concerns.

- Open-ended questions about overall expectations, preferences, and potential purchase intentions are vital to capturing detailed consumer feedback.

Key Factors Influencing Consumer Adoption

Several factors significantly impact consumer adoption of solid-state battery EVs. These factors encompass technological advancements, practical considerations, and societal influences.

- Range anxiety is a major concern for potential EV buyers. The improved range offered by solid-state batteries can directly address this anxiety, encouraging adoption.

- Charging speed and time are important considerations. Solid-state batteries’ potential for faster charging times and reduced charging intervals are critical factors.

- Safety and reliability are paramount for consumer trust. Demonstrating the enhanced safety features and long-term reliability of solid-state battery technology is crucial for encouraging adoption.

- Price point remains a crucial factor. Lower production costs and competitive pricing will influence consumer decisions.

- Public perception and media coverage play a significant role in shaping consumer opinions. Positive portrayals of solid-state battery technology can encourage widespread adoption.

Consumer Preferences and Expectations

Consumer expectations regarding range, charging speed, and safety are pivotal factors.

- Range expectations for solid-state battery EVs should be significantly higher than those of current EV models. Consumers expect a substantial increase in range to reduce range anxiety.

- Faster charging times are a major driver for consumer adoption. The ability to charge quickly and efficiently can significantly reduce the inconvenience associated with EV ownership.

- Safety is paramount. Consumers prioritize the safety and reliability of solid-state battery technology, and this is a key area for marketing and development efforts.

Hypothetical Consumer Purchase Scenario

Consider a consumer, Sarah, who is actively researching EVs. She values range, charging speed, and safety. The prospect of a solid-state battery EV with a significantly longer range and faster charging capability aligns with her needs.

“If the new solid-state battery EV offers a 500+ mile range and significantly faster charging times, I’m confident in making the switch. Safety is paramount, and I want to see concrete evidence that the batteries are reliable and durable.”

Sarah is likely to research various models and compare features before making a purchase. She will likely look for independent testing results and reviews, especially focusing on safety and performance aspects of solid-state battery technology.

End of Discussion

In conclusion, Henrik Fisker’s commitment to solid-state battery technology in electric cars represents a significant step toward a sustainable and exciting future for transportation. The challenges are undeniable, from manufacturing to consumer acceptance, but the potential rewards are equally compelling. This technology promises a greener, faster, and more efficient driving experience, and the journey towards mass adoption is fascinating to follow.