3D printed glass pretzel materials science explores the fascinating world of 3D printing technology applied to glass-based materials. This innovative approach presents unique challenges and opportunities in crafting intricate glass structures, from simple pretzels to complex shapes. We’ll delve into various 3D printing techniques, analyze the material properties of these glass pretzels, and explore the design and fabrication processes involved.

Finally, we’ll investigate potential applications in diverse fields and discuss the hurdles and future research directions.

Imagine creating glass objects with intricate details, customized shapes, and potentially unique optical properties – all thanks to 3D printing. This exploration into 3D printed glass pretzel materials science unveils the scientific principles and practical aspects of this emerging technology. We’ll examine the mechanical, thermal, and optical characteristics of the printed glass, comparing them to traditional glass-forming methods.

This comparison provides insights into the potential advantages and disadvantages of this revolutionary approach.

Introduction to 3D Printed Glass Pretzels

D printing, a rapidly evolving technology, is transforming various fields, including materials science. From intricate medical implants to customized architectural components, 3D printing’s ability to fabricate complex geometries with diverse materials is revolutionizing design and manufacturing. Its application extends to the realm of glass, a material known for its strength and transparency. However, 3D printing glass presents unique challenges, especially when aiming for intricate shapes and precise control over the final product.The potential benefits of 3D printing glass are significant.

Imagine the possibility of creating customized glass components with tailored optical properties or complex structural forms. This technology could open up novel design possibilities and create opportunities for highly specialized applications. The pursuit of 3D printed glass pretzels, though seemingly whimsical, embodies the potential and challenges inherent in this burgeoning field.

Challenges and Opportunities in 3D Printing Glass

D printing glass presents considerable challenges, primarily due to glass’s inherent properties. Glass is notoriously difficult to process in a way that maintains its desired properties during the fabrication process. High temperatures and precise control over the cooling rate are critical factors for maintaining the desired structure and preventing defects. Further complicating matters is the need for appropriate feedstock materials, which must be formulated to be printable and subsequently solidify into the desired shape.

3D Printing Techniques for Glass Materials

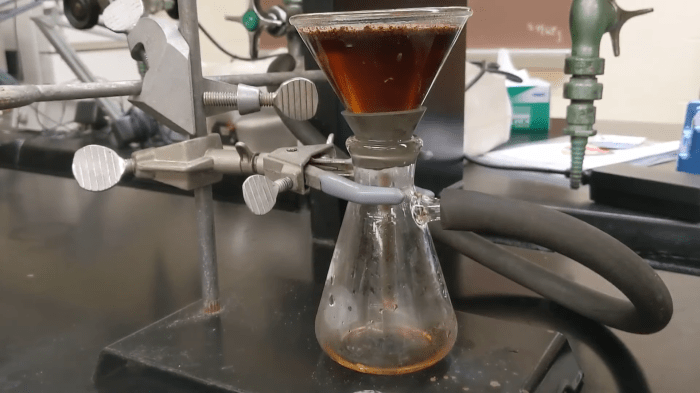

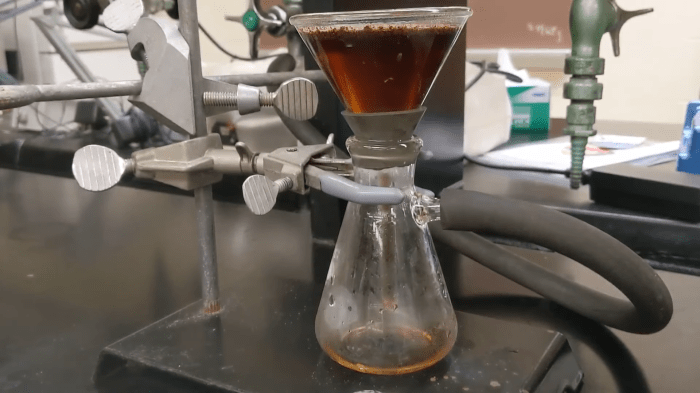

Various 3D printing techniques are being explored for glass materials. One promising approach is binder jetting, where a binder is selectively deposited onto a powder bed of glass particles. The binder fuses the particles, and after removal, a solid glass object remains. Another technique, direct ink writing, involves extruding a viscous glass ink through a nozzle. This method is particularly well-suited for creating intricate shapes and complex geometries.

Stereolithography, a common technique in other 3D printing processes, is also adaptable to glass materials, albeit with specific modifications to accommodate the high temperatures and unique characteristics of glass.

3D printed glass pretzel materials science is fascinating, exploring the possibilities of creating strong, lightweight structures. While researching the intricate properties of these materials, I stumbled across a killer deal on OnePlus Buds Bullets Wireless Z earbuds on Black Friday, oneplus buds bullets wireless z earbuds headphones deal black friday. The potential applications of these innovative materials, like 3D printed glass pretzels, are really exciting and likely to inspire future advancements in various industries.

Comparison of Glass Compositions for 3D Printing

Different glass compositions exhibit varying properties and limitations when subjected to 3D printing. The choice of composition plays a significant role in the success of the process. A table below summarizes common glass compositions, highlighting their key properties and limitations.

| Glass Composition | Properties | Limitations |

|---|---|---|

| Soda-lime glass | Abundant, relatively inexpensive, good transparency | Lower melting point, potentially prone to degradation during printing |

| Borosilicate glass | High thermal stability, good chemical resistance | Higher cost, more complex processing requirements |

| Aluminosilicate glass | High strength, good resistance to thermal shock | Higher melting point, potentially more challenging to print |

| Phosphate glass | High refractive index, potential for unique optical properties | Susceptibility to crystallization during cooling, potential for low toughness |

Different glass compositions will respond differently to the 3D printing process, impacting the final product’s properties and printability. The selection depends on the desired characteristics of the printed object.

Material Properties and Characterization

D-printed glass pretzels, while visually intriguing, present a fascinating challenge in materials science. Understanding their mechanical, thermal, and optical properties is crucial for optimizing the printing process and predicting their performance in various applications. This exploration delves into the specific characteristics of these unique, 3D-fabricated glass structures.The properties of 3D-printed glass pretzels are significantly influenced by the glass composition and the printing parameters.

Factors such as the cooling rate, the type of binder used, and the presence of any impurities directly impact the final product’s characteristics. Precise control over these variables is essential to achieve desired mechanical, thermal, and optical performance.

Mechanical Properties

D-printed glass pretzels exhibit a range of mechanical properties, including strength and elasticity. The inherent brittleness of glass is often a concern, but the specific design and the printing process can affect these properties. Intricate designs, while visually appealing, can reduce the overall strength of the pretzel. Careful consideration of the loading conditions is critical in predicting the structural integrity of these objects.

High strength in 3D-printed glass structures is achievable by strategically optimizing the print path, ensuring minimal internal stresses and maximizing the glass’s inherent strength.

Thermal Properties

The thermal properties of the glass used in 3D-printed pretzels are critical to the printing process and the final product’s stability. The melting point of the glass dictates the maximum temperature achievable during printing. A high melting point is advantageous to ensure the glass doesn’t deform or flow during the printing process. The coefficient of thermal expansion is also crucial, as it influences how the pretzel reacts to temperature changes.

A low coefficient of thermal expansion minimizes thermal stress and the risk of cracking under temperature fluctuations. A precise understanding of the glass’s thermal properties is essential for preventing warping or fracture during cooling and for potential applications involving temperature variations.

Optical Properties

The optical properties of 3D-printed glass pretzels are determined by the glass’s transparency and refractive index. The transparency of the glass directly impacts the visual appeal of the pretzel. The refractive index influences how light interacts with the glass structure, affecting the way the pretzel appears under different lighting conditions. Control over the optical properties is essential for applications that require specific light transmission or reflection characteristics.

Careful control over the printing process and the glass composition can result in 3D-printed pretzels with specific optical characteristics.

Characterization Techniques

Various techniques are employed to characterize the properties of 3D-printed glass materials. These methods are essential to understanding the material’s performance and to identify potential limitations or areas for improvement.

| Technique | Description | Measurement |

|---|---|---|

| Tensile Testing | Measures the material’s ability to withstand tensile forces. | Stress-strain curve, ultimate tensile strength, Young’s modulus |

| Differential Scanning Calorimetry (DSC) | Determines the glass transition temperature, melting point, and other thermal properties. | Temperature-dependent heat flow |

| Refractive Index Measurement | Measures the speed of light through the material. | Refractive index value |

| Scanning Electron Microscopy (SEM) | Provides detailed images of the material’s microstructure. | Surface morphology, internal structure |

Comparison with Traditional Glass-Forming Methods

D printing of glass offers distinct advantages over traditional glass-forming methods. It allows for complex geometries and intricate designs that are impossible or impractical to create using conventional techniques. The precise control over the printing process enables tailoring the material properties to specific applications. However, traditional methods, such as glassblowing or casting, often result in higher production rates and more standardized products.

The choice of method depends on the specific requirements of the application, balancing the unique capabilities of 3D printing against the established advantages of conventional techniques.

Design and Fabrication Processes

Crafting 3D-printed glass pretzels involves a meticulous approach to material selection, parameter optimization, and design modifications to achieve desired mechanical properties. This process hinges on understanding the interplay between printing parameters and the final product’s structural integrity. Careful consideration of these factors is critical for producing high-quality, functional 3D-printed glass pretzels.The design and fabrication process for 3D-printed glass pretzels necessitates a comprehensive understanding of glass properties and the capabilities of fused deposition modeling (FDM) or other suitable 3D printing techniques.

This knowledge is essential for achieving optimal results, considering both the aesthetic and functional aspects of the final product.

Material Selection and Parameter Optimization

Choosing the right glass composition is paramount for 3D printing. Glass formulations with low viscosity at elevated temperatures, while maintaining adequate strength and thermal stability, are crucial for successful printing. The viscosity of the glass dictates the ease of extrusion and the ability to form intricate designs. Factors such as particle size, surface tension, and thermal expansion need to be considered to prevent defects and maintain structural integrity.

Different glass compositions will necessitate variations in printing parameters.

Influence of Printing Parameters on Structure and Properties

Several printing parameters exert significant influence on the final structure and properties of the 3D-printed glass pretzels. Layer thickness, nozzle temperature, and printing speed are key variables that directly impact the resulting geometry, surface quality, and mechanical strength.

- Layer Thickness: Thinner layers generally lead to smoother surfaces but can result in increased printing time. Conversely, thicker layers may lead to visible layering and potentially reduced structural integrity. The optimal layer thickness needs to be determined experimentally based on the chosen glass composition and desired final product quality.

- Nozzle Temperature: This parameter is critical for controlling the viscosity of the molten glass during extrusion. An insufficiently high temperature may lead to insufficient flow, resulting in blockages or inconsistent filament deposition. Conversely, excessively high temperatures might cause the glass to degrade or distort the shape. Finding the optimal temperature balance is crucial for accurate and consistent printing.

- Printing Speed: Printing speed affects the cooling rate of the extruded glass. Faster speeds can lead to more brittle glass, while slower speeds may allow for more viscous flow and potentially better surface quality. The chosen printing speed should be carefully evaluated to ensure proper cooling and prevent defects. The optimal speed depends on the glass’s cooling rate.

Table of Common 3D Printing Parameters and Their Effects

The following table summarizes the common 3D printing parameters and their effects on glass pretzel quality.

| Parameter | Value Range | Effect on Glass Pretzel Quality |

|---|---|---|

| Layer Thickness | 0.1 mm – 0.5 mm | Thinner layers improve surface smoothness but increase printing time. Thicker layers can result in visible layering and reduced structural integrity. |

| Nozzle Temperature | 700°C – 900°C | Optimizing temperature is crucial for maintaining flow and preventing blockages or distortion. Lower temperatures may lead to insufficient flow; higher temperatures can cause degradation. |

| Printing Speed | 10 mm/s – 50 mm/s | Faster speeds lead to faster printing but can result in more brittle glass. Slower speeds may allow for better surface quality but extend printing time. |

Flowchart of 3D Printing Process

The following flowchart illustrates the 3D printing process, encompassing pre-processing, printing, and post-processing steps.[Insert a flowchart here. A flowchart would visually depict the steps in a clear and concise manner. A text-based representation would need a more verbose explanation. A simplified representation would be adequate without a visual.]

Modifying Pretzel Design for Optimized Mechanical Properties

The design of the 3D-printed glass pretzels can be modified to optimize mechanical properties. For example, incorporating internal supports or reinforcing structures can enhance the strength of the pretzels. These modifications should be implemented to counteract inherent weaknesses or improve structural integrity. Consideration of the load paths and stress concentrations is crucial in this design optimization phase.

Applications and Potential Uses

D-printed glass pretzels, a novel material, open doors to a wide range of applications, transcending traditional glass limitations. Their unique properties, combined with the flexibility of 3D printing, offer exciting possibilities across diverse fields. This exploration delves into the potential uses of this material, comparing it to conventional glass and other 3D-printed materials.The ability to create intricate, customized shapes with 3D printing offers significant advantages over traditional glass manufacturing methods, which often restrict designs to simpler forms.

The potential for complex optical components, architectural elements, and even novel scientific instruments is substantial. Further, the material’s inherent properties may lead to performance improvements in specific applications compared to traditional glass.

3D printed glass pretzel materials science is fascinating, especially when you consider the potential applications. It’s like a whole new world of possibilities for architectural design, and I’m particularly interested in how the unique properties of these materials will impact future construction. Recently, I’ve been captivated by the innovative visuals in the tenet trailer christopher nolan imax prologue john david washington robert pattinson , which makes me wonder if these futuristic design principles could influence the way we think about 3D-printed glass pretzels in the future.

Hopefully, future research will further explore these unique materials’ properties and applications in the world of 3D printed glass pretzel structures.

Potential Applications in Optics

D-printed glass pretzels can be designed for intricate optical components, potentially surpassing the capabilities of conventional glass. Their customized shapes could lead to the development of novel lenses, waveguides, and filters with tailored optical properties. The precision achievable in 3D printing allows for the creation of highly complex optical structures not possible with traditional methods.

Potential Applications in Architecture

The aesthetic appeal and structural integrity of 3D-printed glass pretzels could revolutionize architectural design. The material’s translucency allows for the creation of stunning light-filtering facades and decorative elements. Furthermore, the intricate patterns and shapes possible with 3D printing could produce unique and eye-catching architectural designs. This could lead to innovative building facades, interior partitions, and even entire structures, especially in areas that value light and unique design.

Advantages and Disadvantages Compared to Traditional Glass

| Feature | 3D Printed Glass Pretzels | Traditional Glass |

|---|---|---|

| Shape Complexity | High | Low |

| Customization | High | Low |

| Manufacturing Cost | Potentially higher for complex shapes | Lower for simple shapes |

| Material Properties | Tailorable | Generally uniform |

| Production Speed | Faster for prototyping, potentially faster for production in the future | Slower |

D printed glass pretzels offer significant advantages in terms of design flexibility, enabling intricate structures not easily attainable with traditional methods. However, the current manufacturing costs might be higher for complex shapes.

3D printed glass pretzels are fascinating from a materials science perspective, but finding the perfect spot for a pretzel-tasting experience can be tricky. Fortunately, you can leverage Google Maps to discover local recommendations for delicious pretzels and other culinary delights. Using features like user reviews and ratings, how get restaurant recommendations google maps can help pinpoint the best spots for a taste-bud adventure.

Ultimately, the materials science behind these 3D printed glass pretzels is still a burgeoning field, but knowing where to find top-notch pretzel options is a crucial part of the journey.

Comparison with Other 3D Printed Materials

Compared to other 3D-printed materials, 3D printed glass pretzels offer a unique combination of optical properties and mechanical strength. While polymers excel in flexibility and low cost, they lack the optical clarity of glass. Metal 3D printing is often used for structural applications, but struggles with the intricate designs and optical properties achievable with this new material. The combination of glass’s optical transparency and the 3D-printed shape-forming capability is a unique advantage, potentially opening new avenues in diverse fields.

For instance, the intricate and customized structures possible with this material may offer improved performance in optical components, surpassing the capabilities of other 3D printed materials.

Future Potential in Materials Science

The future of 3D printed glass pretzels in materials science is promising. As the technology matures, we can expect a wider range of applications and more tailored material properties. The ability to design and fabricate glass components with complex shapes and tailored optical properties could lead to advancements in areas such as photonics, microscopy, and even medical imaging.

The ability to incorporate various glass types and dopants into the 3D printing process opens doors to creating customized materials with specific functionalities, pushing the boundaries of material science. For instance, future research might focus on incorporating specific dopants into the glass to alter its optical properties, allowing for creation of specific filters, waveguides, or lenses.

Challenges and Future Research Directions

D printing glass, while promising, faces significant hurdles. From the delicate nature of the material to the complexities of controlling the printing process, achieving reliable and consistent results remains a challenge. This section delves into the specific difficulties and explores potential avenues for future research in this burgeoning field. We will also look at innovative experimental approaches and their potential to unlock the full potential of 3D printed glass objects.

Material Handling and Control

Precise control over glass flow during the 3D printing process is critical. Glass, with its high viscosity and tendency to solidify quickly, presents unique handling challenges. Current methods often struggle to maintain the desired viscosity while preventing premature solidification, leading to inconsistencies in the final product. Controlling the deposition of molten glass onto the build platform requires advanced understanding of the interplay between material properties and the printing parameters.

Post-Processing Considerations

Post-processing steps are crucial for 3D printed glass objects. These often include annealing to relieve internal stresses, which can significantly affect the mechanical properties and long-term stability of the final product. Developing efficient and cost-effective post-processing techniques is an important area for research. The challenges extend to the potential for glass degradation or structural weakening during these processes.

Minimizing these issues will be critical for successful commercialization.

Impact of Glass Composition on Mechanical Properties

The mechanical properties of 3D printed glass are strongly influenced by the glass composition. Different compositions exhibit varying degrees of strength, toughness, and thermal stability. Investigating the relationships between these parameters is crucial for optimizing the material properties for specific applications. This requires systematic studies, varying the glass composition and measuring the resulting mechanical properties.

Experimental Design: Impact of Glass Composition

A potential experiment to investigate the effect of glass composition on mechanical properties could involve the following steps:

- Select a range of glass compositions with varying ratios of silica, alumina, and other oxides.

- Prepare samples of each composition for 3D printing using a consistent printing parameter set.

- Characterize the mechanical properties of each printed sample, including tensile strength, flexural strength, and hardness.

- Analyze the results to identify correlations between glass composition and mechanical properties. Statistical analysis can provide insights into the significance of these correlations.

This experiment will provide a systematic approach to understanding the effect of glass composition on the mechanical properties of 3D printed glass. The data collected will help guide the development of optimal glass compositions for specific applications.

Current Research Efforts, 3d printed glass pretzel materials science

Researchers are actively exploring ways to improve the material handling and control during 3D printing. Several groups are focusing on advanced techniques such as laser-assisted deposition and the use of specialized nozzles. These approaches aim to mitigate the challenges associated with glass viscosity and solidification.

Creating Complex Shapes

D printing offers the potential to create complex and intricate glass shapes that are difficult or impossible to produce using traditional methods. The ability to fabricate customized, high-quality components with intricate geometries is a significant advantage. This opens avenues for innovative designs in various fields, from optics and art to specialized scientific instruments. For example, researchers have used 3D printing to create complex optical components with intricate patterns, showcasing the potential for advanced functionalities.

Final Thoughts: 3d Printed Glass Pretzel Materials Science

In conclusion, 3D printed glass pretzels, while still in its nascent stage, showcase a remarkable potential to revolutionize glass manufacturing. The detailed exploration of materials science, design, and fabrication processes reveals the intricacies of this emerging technology. While challenges remain, the potential applications in optics, architecture, and other fields are exciting. Further research and development will be crucial to overcome these hurdles and unlock the full potential of 3D printed glass materials.