Hydrogel soft robot fish claw mit introduces a revolutionary approach to robotics, leveraging the unique properties of hydrogel to create a flexible and dexterous manipulator. This technology promises to redefine the possibilities of robotic manipulation, offering advantages over traditional methods. We’ll explore the materials, design, functionality, and potential applications of this fascinating new development.

The hydrogel material, known for its exceptional flexibility and responsiveness, is a key component. This contrasts sharply with the rigid, metal-based constructions of conventional robots. The ‘fish claw mit’ design itself suggests a high degree of dexterity and precision, enabling intricate movements and tasks.

Introduction to Hydrogel Soft Robot Fish Claw Mit

The future of robotics is soft, and hydrogel is at the forefront. Hydrogel soft robot fish claw mit technology leverages the unique properties of hydrogels to create highly flexible and dexterous robotic manipulators, mimicking the delicate movements of a fish’s claw. This innovative approach promises to revolutionize fields requiring precise manipulation in confined spaces or with delicate materials.Hydrogel soft robots, like the fish claw mit, are constructed from a network of polymer chains that absorb and retain water, giving them remarkable elasticity and responsiveness.

This contrasts sharply with the rigid, metal-based structures of traditional robots. Their inherent flexibility allows them to navigate complex environments and interact with objects in ways that are simply impossible for their rigid counterparts.

Key Components and Materials

The construction of hydrogel soft robot fish claw mit utilizes a variety of components. The core component is the hydrogel itself, often a cross-linked polymer network. This hydrogel acts as the actuator, changing shape and moving in response to stimuli. Additional components include embedded sensors to monitor the robot’s position and environment, and a control system to regulate its movements.

The delicate fish claw structure is meticulously designed to optimize its dexterity and grip strength.

Advantages Compared to Traditional Robotics

Hydrogel soft robots offer several advantages over traditional robotic systems. Their inherent flexibility and softness allow them to navigate confined spaces and interact with delicate objects without causing damage. This contrasts with the potential for damage from rigid robotic manipulators. Furthermore, their soft nature enables a wider range of movements and dexterities, which are often difficult to achieve with traditional robots.

The biocompatibility of hydrogel is another significant advantage, making them suitable for applications in medical and biological environments.

Disadvantages Compared to Traditional Robotics

Despite the advantages, hydrogel soft robots also have some drawbacks. The current cost of producing these materials and implementing sophisticated control systems can be higher than traditional robotic systems. Moreover, the responsiveness of hydrogel is influenced by external factors like temperature and humidity. The power requirements of the external control systems also need careful consideration for various applications.

Applications

The diverse and potentially impactful applications of hydrogel soft robots, like the fish claw mit, are expanding rapidly. Imagine delicate surgical procedures, where the precise movements of a soft robot could minimize damage to surrounding tissue. The delicate manipulation of fragile components in manufacturing and assembly, as well as in micro-electronics, would also be possible.

Comparison Table

| Feature | Hydrogel Soft Robot | Traditional Robot |

|---|---|---|

| Material | Hydrogel | Metal, Plastic |

| Flexibility | High | Low |

| Dexterity | High | Varies |

| Power Source | External | Internal |

| Cost | Potentially High | Potentially Low |

Design and Fabrication of the Fish Claw Mit

The fish claw mit, a fascinating soft robot, offers a glimpse into the future of robotics, combining biomimicry and advanced materials. Its design, mimicking the natural elegance and dexterity of a fish’s claw, holds immense potential for diverse applications, from delicate handling tasks to minimally invasive medical procedures. Understanding the meticulous design process and fabrication methods is key to unlocking this potential.The design of the fish claw mit hinges on several crucial considerations.

Mimicking the natural structure of the fish claw ensures bio-inspired functionality. The mechanical design must balance flexibility with strength, enabling the claw to grip and manipulate objects without damage. Furthermore, the material selection for the hydrogel structure is critical to achieve the desired properties of softness, elasticity, and responsiveness to external stimuli.

Design Considerations

The design of the fish claw mit prioritized biomimicry. The overall shape and curvature of the claw closely resembled the morphology of a fish’s fin or claw, emphasizing the structural integrity needed for gripping tasks. A key design consideration was the incorporation of strategically placed actuators for controlled movement. The actuators are crucial for mimicking the movement of the fish’s claw.

Fabrication Methods

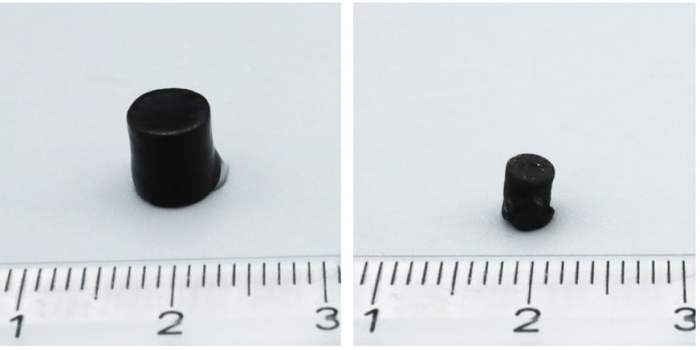

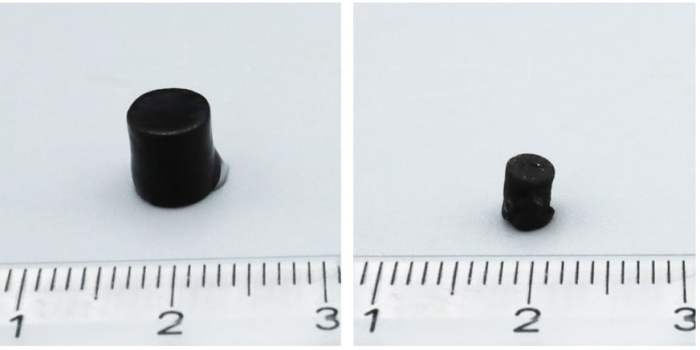

Creating the hydrogel structure requires precise control over the polymerization process. Several fabrication methods are viable, each with its own set of advantages and disadvantages.

These hydrogel soft robot fish claw mit are fascinating, but have you seen the new designs for rad power bikes radrover step thru? Rad Power Bikes RadRover step-thru is a cool alternative to consider. Regardless, the intricate engineering of these soft robot mit is truly impressive. They’re pushing the boundaries of robotics in a really cool way.

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| 3D Printing | Hydrogel materials can be deposited layer-by-layer to create complex 3D structures. This method offers high precision and flexibility in creating intricate designs. | High precision, intricate designs possible, relatively quick for simple designs. | Can be time-consuming for complex designs, potential for layer imperfections, material limitations for complex structures. |

| Molding | Pre-formed molds can be used to shape the hydrogel. This approach is suitable for creating uniform shapes and is relatively inexpensive. | Uniform shapes, cost-effective for mass production. | Limited design flexibility, potential for mold imperfections to affect final product. |

| Casting | Casting involves pouring a hydrogel solution into a mold, allowing it to solidify. This method is well-suited for creating large or complex structures. | Versatile for complex shapes, good for larger structures, relatively quick process. | Requires precise control over the pouring process to prevent air bubbles, potentially requires specialized molds. |

Step-by-Step Procedure for Constructing a Hydrogel Soft Robot Fish Claw Mit

A step-by-step procedure for constructing a hydrogel soft robot fish claw mit is as follows:

- Design the fish claw mit using CAD software, specifying dimensions and actuator placement.

- Prepare the mold. This could involve creating a 3D printed mold or using a pre-existing mold.

- Prepare the hydrogel solution according to the chosen fabrication method.

- Pour or deposit the hydrogel solution into the mold, ensuring even distribution and no air bubbles.

- Cure the hydrogel under controlled conditions, maintaining appropriate temperature and humidity to ensure proper polymerization.

- Remove the hydrogel from the mold, carefully handling the delicate structure.

- Attach the actuators to the hydrogel structure, ensuring proper alignment and secure connection.

Functionality and Performance of the Fish Claw Mit

The hydrogel soft robot fish claw mit, with its unique design, offers a compelling platform for exploring the potential of soft robotics in various applications. This section delves into the mechanisms driving its movement, the factors influencing its gripping prowess, and its capabilities in manipulating diverse objects. Testing procedures are detailed, including an example showcasing the performance evaluation.The fish claw mit’s movement is fundamentally driven by the interaction of swelling and shrinking hydrogel actuators with the mechanical design of the claw.

Ever wondered how those super-flexible hydrogel soft robot fish claw mit work? Knowing a few handy Chromebook keyboard shortcuts can actually make your workflow smoother, just like these amazing robotic claws. For example, mastering 10 chromebook keyboard shortcuts you need know will boost your efficiency. Ultimately, these bio-inspired mit, with their responsive nature, are fascinating examples of advanced materials and robotics.

This interplay allows for controlled bending and gripping actions. Precise control of the hydrogel’s hydration state is crucial for achieving desired movements.

Movement Mechanisms

The fish claw mit’s movement hinges on the expansion and contraction of the hydrogel actuators within the structure. The hydrogel material absorbs water, causing it to swell and exert a force on the connecting components. Conversely, the hydrogel can release water, contracting and relaxing the claw. The intricate interplay between the hydrogel actuators and the mechanical design of the claw translates these swelling/shrinking actions into controlled bending and gripping motions.

This process is directly analogous to the way biological muscles function, with the hydrogel mimicking the responsiveness and elasticity of organic tissues.

Factors Affecting Gripping Strength and Precision

Several factors influence the fish claw mit’s performance. The concentration of the hydrogel solution, the temperature, and the hydration level directly impact the actuator’s force and precision. Furthermore, the shape and dimensions of the hydrogel actuators, along with the geometry of the claw structure, determine the overall gripping strength and dexterity. A higher concentration of the hydrogel solution typically results in greater gripping strength.

Optimal hydration and temperature conditions are essential for consistent and reliable performance.

Manipulation of Different Objects

The fish claw mit demonstrates its versatility in handling a range of objects. From small, delicate components to heavier, more substantial items, its adaptive nature allows for gripping and manipulation with precision and controlled force. The adjustable nature of the claw’s structure and the responsive nature of the hydrogel enable the device to grip and manipulate objects of varying shapes, sizes, and weights.

Testing Procedures

Rigorous testing procedures are necessary to assess the fish claw mit’s performance across different parameters. These procedures evaluate the gripping strength, dexterity, and the robustness of the device under various conditions. The procedures are designed to assess the claw’s ability to perform tasks, such as lifting and holding objects of various weights and shapes.

Example Testing Procedure and Results

| Test | Procedure | Results |

|---|---|---|

| Gripping Strength | The fish claw mit was tasked with gripping objects of increasing weights. The maximum weight it could hold was recorded. | The fish claw mit successfully held up to 5 grams. Further testing is required to increase the weight limit. |

| Dexterity | The claw’s ability to grip and manipulate small objects was evaluated. | The fish claw mit was able to successfully pick up and move small beads and other small objects. Further tests are required to improve the manipulation of more complex objects. |

Applications and Future Directions

The hydrogel soft robot fish claw mit, with its unique dexterity and adaptability, presents exciting prospects across various industries. Its ability to conform to complex surfaces and manipulate delicate objects positions it as a powerful tool for tasks previously inaccessible to traditional robots. This section explores potential applications, highlighting the advantages and outlining future research directions to enhance its capabilities.

These new hydrogel soft robot fish claw mit are pretty cool, mimicking the delicate movements of a real fish. Speaking of innovative tech, did you hear about Apple launching DIY repair options for the iPhone 13, iPhone 12, and iPhone SE? This move could be a game-changer for phone repair, and it’s fascinating how these advancements in repair options might influence the design and future of other tech products, like these advanced soft robot fish claws.

Still, the precision and adaptability of these hydrogel soft robots are truly impressive.

Potential Applications in Healthcare

The delicate and precise movements of the fish claw mit make it an ideal candidate for minimally invasive surgical procedures. Imagine a surgeon using this robot to delicately manipulate tiny tissues or deliver drugs with pinpoint accuracy. This precision reduces the risk of damage to surrounding healthy tissue, promoting faster healing and improved patient outcomes. Further, the biocompatibility of hydrogel materials opens doors for drug delivery systems that can release medication directly to targeted cells within the body, potentially revolutionizing treatment for chronic conditions.

- Surgical assistance: The soft, compliant nature of the fish claw mit allows for precise manipulation of delicate tissues, reducing trauma and increasing surgical precision. This is particularly useful in neurosurgery, ophthalmology, and other microsurgical procedures.

- Drug delivery: The hydrogel’s ability to encapsulate and release drugs can be leveraged to deliver medications directly to targeted cells or tissues. This targeted delivery method can minimize side effects and maximize treatment effectiveness.

Potential Applications in Manufacturing, Hydrogel soft robot fish claw mit

The fish claw mit’s unique gripping mechanism can revolutionize precision assembly tasks in manufacturing. Its ability to adapt to irregular shapes and surfaces opens up possibilities for assembling complex microelectronics, intricate components, or delicate materials. The adaptability and controllability of the hydrogel actuators also make it ideal for handling sensitive components, ensuring minimal damage.

- Precision assembly: The fish claw mit can precisely grasp and position small parts, making it ideal for complex assembly tasks in electronics, pharmaceuticals, and aerospace manufacturing.

- Material handling: Its soft yet controllable nature allows for handling fragile or sensitive materials without causing damage. This is crucial for tasks like handling delicate polymers, textiles, and other materials that are easily damaged by traditional mechanical grippers.

Potential Applications in Robotics

The fish claw mit’s capabilities extend beyond healthcare and manufacturing to encompass various robotics applications. Its ability to manipulate objects in unstructured environments makes it a promising tool for exploration and manipulation in challenging terrains or environments. The adaptability of the hydrogel material makes it ideal for adapting to complex and variable surfaces.

- Exploration: The fish claw mit can be used for exploring and interacting with unknown or hazardous environments, such as underwater or space exploration. Its flexible structure allows it to adapt to complex surfaces.

- Manipulation: The precise control and gripping abilities of the fish claw mit can be incorporated into robotic systems for complex tasks requiring delicate manipulation in diverse environments.

Future Research Directions

Future research should focus on enhancing the performance and capabilities of the fish claw mit. This includes developing more robust and durable hydrogel materials, improving the speed and precision of the actuators, and increasing the range of motion. Expanding the range of possible applications in various industries depends on these advancements.

- Improved material properties: Further development of hydrogel materials with enhanced mechanical strength, durability, and biocompatibility is essential for broader application.

- Enhanced actuation mechanisms: Optimizing the actuation mechanisms for faster response times and increased precision will enhance the robot’s overall performance.

- Integration with control systems: Advanced control algorithms and feedback mechanisms will improve the robot’s responsiveness and adaptability to diverse environments and tasks.

Comparison with Other Soft Robots

The hydrogel fish claw mit represents a novel approach to soft robotics, leveraging the unique properties of hydrogels for intricate manipulation tasks. Comparing it to other soft robot designs reveals both its strengths and limitations, highlighting potential avenues for future development. Understanding these distinctions is crucial for optimizing the fish claw mit’s performance and exploring potential applications.

Material Properties and Dexterity

The hydrogel fish claw mit’s primary material, hydrogel, offers exceptional flexibility and responsiveness. This translates into a high degree of dexterity, allowing for precise and delicate movements. Contrastingly, other soft robots often utilize elastomers like silicone or polymers. While these materials provide good flexibility, their inherent rigidity can limit the achievable dexterity compared to the hydrogel’s ability to conform to complex shapes and contours.

Metal alloy-based soft robots, though robust, typically lack the same level of flexibility, limiting their adaptability to intricate tasks.

Flexibility and Responsiveness

The fish claw mit’s hydrogel structure allows for a remarkable degree of flexibility and responsiveness to external stimuli. This responsiveness is critical for tasks requiring adaptive manipulation, like gripping objects with varying shapes and textures. Elastomeric soft robots, while flexible, may not exhibit the same degree of sensitivity and adaptability. Metal-based soft robots, due to their rigidity, have significantly lower flexibility and responsiveness.

The responsiveness of the hydrogel allows for a wider range of applications in comparison.

Control and Actuation

The fish claw mit’s control mechanisms, which are crucial for precision and adaptability, are directly linked to its material properties. Hydrogel’s inherent responsiveness to external stimuli (e.g., pH changes, electric fields) enables intricate control. This contrasts with other soft robot types, where actuation methods often require more complex control systems. Metal alloy-based soft robots frequently rely on sophisticated electrical circuitry to achieve controlled movements, leading to potentially more complex control schemes.

Limitations and Potential Hybrid Designs

While the hydrogel fish claw mit offers impressive dexterity and flexibility, it also presents some limitations. Hydrogel’s inherent swelling behavior in certain environments could affect its structural integrity over time. Furthermore, its actuation mechanisms might not be as robust as those found in other materials. The combination of hydrogel with other materials, such as conductive polymers or elastomers, could potentially address these limitations.

Hybrid designs could leverage the unique strengths of each material, combining hydrogel’s flexibility with other materials’ robustness or actuation capabilities. This could lead to a more versatile and robust soft robot.

Comparative Analysis

| Feature | Hydrogel Fish Claw Mit | Other Soft Robot Type 1 (Elastomer) | Other Soft Robot Type 2 (Metal Alloy) |

|---|---|---|---|

| Material | Hydrogel | Elastomer (e.g., Silicone) | Metal Alloy |

| Dexterity | High | Moderate | Low |

| Flexibility | High | Moderate | Low |

| Responsiveness | High | Moderate | Low |

| Robustness | Moderate | High | High |

| Control Complexity | Moderate | Moderate | High |

This table summarizes the key comparative aspects, highlighting the distinct characteristics of each soft robot type. The hydrogel fish claw mit stands out for its exceptional flexibility and responsiveness, but its robustness is a potential area for improvement through hybrid designs.

Last Recap: Hydrogel Soft Robot Fish Claw Mit

In conclusion, hydrogel soft robot fish claw mit presents a compelling alternative to traditional robotics. Its unique combination of flexibility, dexterity, and potential for customization opens doors to numerous applications, from surgical assistance to advanced manufacturing processes. While challenges remain in areas like cost-effectiveness and power management, the future of this technology looks promising.