3D printed prosthetics turned into musical instruments is a fascinating concept. Imagine transforming a limb replacement into a unique instrument, harnessing the power of 3D printing to create something both functional and sonically innovative. This exploration delves into the design, engineering, and musical potential of such prosthetic instruments, exploring the possibilities and challenges inherent in this intersection of technology and artistry.

We’ll examine the materials, design processes, and user experience, offering a glimpse into the future of musical creation and accessibility.

From the initial design to the final sound, this innovative approach opens up new creative avenues. The unique challenges in crafting instruments from prosthetics are balanced by the potential to create truly personalized and unique musical experiences.

Introduction to 3D Printed Prosthetics as Musical Instruments

D printing has revolutionized numerous industries, and prosthetics are no exception. The ability to create customized, intricate designs has dramatically improved the quality of life for amputees, allowing for greater functionality and improved aesthetics. This burgeoning technology is now extending into the realm of art and creativity, with some prosthetics being adapted into unique musical instruments.This exploration delves into the intersection of 3D printing, prosthetics, and musical instruments, examining the materials, design considerations, and potential applications of this innovative approach.

The potential for personalized musical experiences, coupled with the therapeutic benefits of music, is a fascinating aspect of this emerging field.

History of 3D Printing in Prosthetics

D printing’s impact on prosthetics began with its ability to rapidly create custom-fit designs. Early applications focused on improving the fit and comfort of limb replacements, often using polymers like ABS and PLA. As 3D printing technology advanced, so did the materials and design complexity, leading to more sophisticated and functional prosthetics. The evolution from simple replacements to complex, intricate designs, including the incorporation of sensors and actuators, demonstrates the rapid development of this technology.

Types of 3D Printed Prosthetics

Various types of 3D printed prosthetics exist, tailored to specific needs. These include:

- Below-knee and above-knee replacements: These are common types, often featuring intricate designs to support the remaining limb and facilitate movement.

- Hand prosthetics: These are more complex, requiring a precise understanding of hand anatomy and functionality. 3D printing enables the creation of customized designs that replicate the shape and movement of a natural hand, improving dexterity and control.

- Facial prosthetics: These are crucial for reconstructing facial features lost due to injury or birth defects. 3D printing offers the potential for intricate designs and precise fit, restoring both function and aesthetics.

Materials Used in 3D Printed Prosthetics

The choice of material is critical in prosthetic design, considering factors like strength, durability, biocompatibility, and aesthetic appeal. Common materials include:

- Polylactic acid (PLA): A biocompatible polymer often used for early prototyping and simpler designs due to its relatively low cost and ease of use.

- Acrylonitrile butadiene styrene (ABS): A strong and durable polymer, commonly used for functional prosthetics, offering a balance between strength and cost-effectiveness.

- Carbon fiber-reinforced polymers: These offer superior strength and stiffness, making them suitable for high-load-bearing applications. They are increasingly used in advanced prosthetic designs.

Adapting 3D Printed Prosthetics for Other Purposes

Beyond their primary function as replacements, 3D printed prosthetics have been adapted for various purposes. These adaptations showcase the versatility and adaptability of the technology.

- Sculptural art: The ability to create complex forms has led to the use of 3D printed prosthetics as artistic mediums, showcasing the potential for creative expression beyond their medical applications.

- Educational tools: Simplified versions of prosthetics can be used in educational settings to teach students about anatomy, engineering, and design.

- Specialized tools: In certain industrial contexts, custom-designed prosthetics can be utilized as specialized tools, tailored to specific tasks and ergonomics.

Converting Prosthetics into Musical Instruments

The concept of converting prosthetics into musical instruments builds on the customization and personalization capabilities of 3D printing. The unique shapes and designs of prosthetics can be adapted to create novel musical instruments, potentially offering a new form of artistic expression for amputees and inspiring innovative musical designs.

3D printed prosthetics are becoming more than just replacements; they’re transforming into instruments! Imagine a prosthetic limb that not only restores function but also produces music. This innovative approach is truly inspiring. Meanwhile, if you’re looking for the latest news on the Sennheiser CX Plus true wireless earbuds, including noise cancellation release dates and features, check out this helpful resource: sennheiser cx plus true wireless earbuds noise cancellation release date news features.

The future of these 3D printed musical instruments is buzzing with exciting possibilities, and I’m eager to see what comes next.

Advantages and Disadvantages of Using 3D Printed Prosthetics as Musical Instruments

| Feature | Advantage | Disadvantage |

|---|---|---|

| Material | Customizable, potentially biocompatible, diverse range of options (PLA, ABS, carbon fiber). | Material properties may not be optimal for all musical instruments; durability and resonance may vary. |

| Design | Highly customizable, allows for unique and personalized instruments; intricate designs can be easily implemented. | Complex designs may be challenging to manufacture, leading to higher production costs and potential issues with manufacturing tolerances. |

| Functionality | Can potentially enhance musical expression and artistic expression through the integration of the prosthetic. | Functional aspects of the prosthetic as a musical instrument may be limited by the design and material choices. |

Design and Engineering Considerations

Transforming a prosthetic limb into a musical instrument presents a unique blend of medical, engineering, and artistic challenges. The design process necessitates a careful consideration of biocompatibility, functionality, and the desired sonic output. This involves understanding the patient’s needs and capabilities, as well as the specific musical requirements. The aim is to create a prosthetic instrument that is not only functional but also aesthetically pleasing and engaging.

Design Process for Converting a Prosthetic into a Musical Instrument

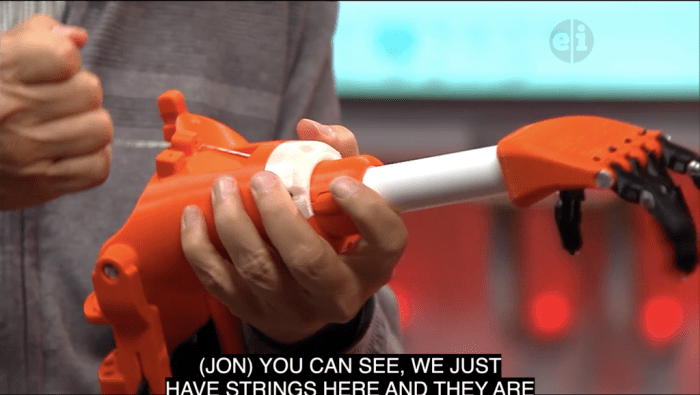

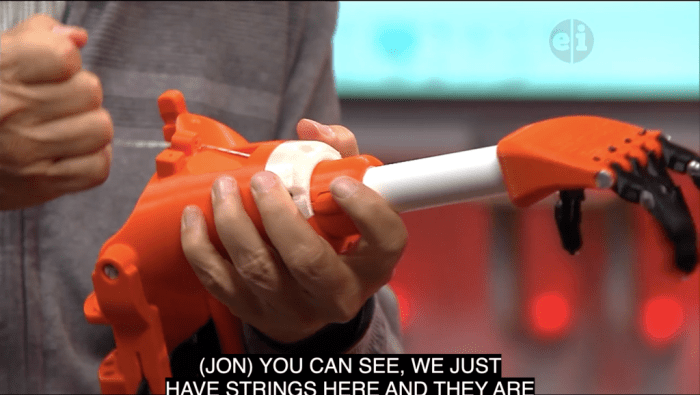

The design process starts with a thorough understanding of the patient’s needs, including their existing prosthetic, desired musical style, and physical limitations. Detailed measurements and 3D scans of the prosthetic limb are crucial for accurate design and fabrication. CAD software is used to create a digital model of the instrument, integrating the prosthetic’s shape and dimensions. This design must incorporate the necessary mechanical components, such as actuators and sensors, for sound production and control.

Prototyping is essential to refine the design and assess the instrument’s functionality and playability. Iterative testing and feedback from the patient and musicians are vital for achieving a successful outcome.

Engineering Challenges in Creating Musical Instruments from Prosthetics

Several engineering challenges arise when converting prosthetics into musical instruments. Biocompatibility is paramount; the materials used must not only produce the desired sound but also be compatible with the human body. Precise mechanical tolerances are needed for smooth and reliable sound production. The instrument must be lightweight and comfortable to use. Integrating sensors and actuators for control can be complex and require careful consideration of space constraints and power requirements.

The integration of electronic components into the prosthetic structure must adhere to safety standards. Furthermore, the instrument must be durable enough to withstand the rigors of daily use.

Types of Sensors and Actuators

Various sensors and actuators can be integrated into the prosthetic instrument. Force sensors can detect the pressure applied to the prosthetic, while accelerometers can measure vibrations. These sensors provide data for controlling the sound output. Actuators, such as piezoelectric transducers or electromagnetic components, can generate the necessary vibrations for sound production. The choice of sensors and actuators depends on the specific instrument design and desired sound characteristics.

For instance, a plucked string instrument might use force sensors to determine the pluck strength, while a wind instrument might use pressure sensors to control air flow.

Methods for Controlling the Sound Produced by the Prosthetic Instrument

Controlling the sound produced by the prosthetic instrument can be achieved through various methods. A simple control system might use a single button or lever to activate the instrument. More complex systems can utilize sophisticated algorithms to generate different sounds based on the user’s movements. The user interface can be tailored to the specific needs and abilities of the individual.

Advanced control mechanisms might incorporate sensors embedded in the prosthetic limb, allowing the user’s movements to directly influence the sound output.

Examples of Different Musical Instruments Created from Prosthetics

A range of instruments can be created from prosthetics. A prosthetic hand could be modified to create a plucked string instrument, where the fingers act as plucking mechanisms. A prosthetic arm could be fashioned into a percussion instrument, using a series of sensors to detect striking force and thus generate different rhythmic patterns. Another possibility is a prosthetic leg that generates sound through vibrations controlled by the user’s movement, acting as a unique wind instrument.

Table Comparing Design Specifications of Prosthetic-Based Instruments

| Instrument Type | Material | Sound Production Method | Control Mechanism |

|---|---|---|---|

| Prosthetic Hand String Instrument | 3D-printed polymer, metal strings | Plucking of strings by prosthetic fingers | Force sensors on prosthetic fingers |

| Prosthetic Arm Percussion Instrument | 3D-printed polymer, metal plates | Striking of metal plates by prosthetic arm | Accelerometers and force sensors on prosthetic arm |

| Prosthetic Leg Wind Instrument | 3D-printed polymer, resonating chambers | Airflow through resonating chambers | Pressure sensors on prosthetic leg |

Sound Production and Musicality: 3d Printed Prosthetics Turned Into Musical Instruments

Transforming 3D-printed prosthetics into musical instruments opens up a world of sonic possibilities. The unique shapes, materials, and mechanisms employed in these prosthetics can be meticulously engineered to produce a wide array of sounds, challenging traditional notions of instrument design. This exploration delves into the methods of sound production, the diverse sonic palettes achievable, and the potential for creating entirely new musical genres.The sound production in these prosthetic instruments relies heavily on the design of the 3D-printed components themselves.

Precisely engineered resonating chambers, coupled with carefully selected materials, can dramatically affect the sound quality. The shape of the prosthetic, its internal structure, and the type of material used can all be manipulated to control the pitch, timbre, and overall character of the sound. Furthermore, these instruments can incorporate various mechanical components to generate percussion-like sounds, further expanding the expressive range.

3D printed prosthetics are becoming more than just replacements; some are being transformed into surprisingly beautiful musical instruments. This innovative approach opens up a whole new world of creative expression. For instance, someone like a dedicated fan of the Lord of the Rings films, perhaps even a huge Tolkien enthusiast, or a fan of Peter Jackson’s movies , might find this idea particularly fascinating.

Ultimately, these customized musical instruments, born from 3D-printed prosthetics, are a testament to the incredible potential of technology and artistry combined.

Methods of Sound Production

D-printed prosthetic instruments can utilize a variety of sound production methods. Some designs employ vibrations from the prosthetic itself, while others incorporate external mechanisms like hammers or strings. The choice of method significantly influences the instrument’s timbre and musical capabilities. For example, a prosthetic arm with a precisely sculpted internal cavity can resonate at specific frequencies, producing a sustained, almost melodic tone.

Alternatively, a prosthetic leg might incorporate a series of metal plates that strike each other, producing rhythmic percussion.

Sound Qualities Achievable, 3d printed prosthetics turned into musical instruments

The diverse sound qualities attainable with these instruments are a direct result of the various design parameters. These parameters include material selection, component geometry, and the incorporation of mechanical elements. For instance, using a lightweight polymer for a resonating chamber can yield a bright, airy tone, whereas a denser metal might produce a warmer, more resonant sound. The shape of the prosthetic can also be instrumental in shaping the sound.

A pointed tip, for instance, might produce a sharp, percussive sound, while a rounded surface might yield a more mellow, sustained tone.

Comparison to Traditional Instruments

While 3D-printed prosthetic instruments share some similarities with traditional instruments, they also offer unique sonic possibilities. The ability to tailor the shape and material of the prosthetic allows for a wider range of sound characteristics compared to traditional instruments, which often have fixed designs. This adaptability allows for a unique exploration of timbre and sound dynamics. Traditional instruments often have established sonic characteristics, whereas these 3D-printed instruments can have sounds that defy easy categorization, leading to a unique sonic landscape.

Unique Musical Possibilities

These prosthetic instruments open doors to unprecedented musical possibilities. The ability to create instruments with highly personalized sound characteristics allows for the exploration of new musical genres and expression. Composers can craft pieces that are tailored to the specific sonic output of each instrument, leading to highly individual and innovative musical expressions. The unique interplay of sounds from these instruments could lead to new and innovative forms of musical composition.

Potential for New Musical Genres

The unique and customizable nature of these instruments opens the door to a vast potential for developing entirely new musical genres. The distinctive sounds and possibilities for experimentation can lead to the creation of music that pushes the boundaries of existing genres. Imagine musical pieces designed specifically to take advantage of the complex and unpredictable timbres these instruments can produce.

This potential for innovation in musical expression is truly groundbreaking.

Sound Frequencies of Prosthetic Instruments

| Instrument | Frequency Range (Hz) | Timbre |

|---|---|---|

| 3D-Printed Hand Percussion | 200-1000 Hz | Percussive, sharp, metallic |

| 3D-Printed Arm Resonator | 50-500 Hz | Sustained, mellow, resonating |

| 3D-Printed Leg Striker | 100-800 Hz | Rhythmic, percussive, low-pitched |

The table above presents a preliminary overview of the potential sound frequencies. Further experimentation and refinement of the design parameters will likely yield even more diverse and nuanced sounds. It’s important to note that these are just examples, and the actual frequencies can vary significantly based on specific design elements.

User Experience and Accessibility

D-printed prosthetic instruments, while promising, must prioritize user experience to be truly impactful. This section delves into the practical considerations for individuals using these instruments, focusing on the benefits, challenges, and strategies for enhancing usability and accessibility. The goal is to create instruments that are not only aesthetically pleasing but also functional and empowering for the users.

User Experience of Playing 3D Printed Prosthetic Instruments

The user experience of playing a 3D-printed prosthetic instrument is multifaceted. It encompasses not only the physical interaction with the instrument but also the emotional and psychological response to the sound and the overall experience. Successful instruments will allow for a wide range of expressive possibilities, mimicking the versatility of traditional instruments.

Potential Benefits for Individuals with Limb Differences

D-printed prosthetic instruments offer unique benefits for individuals with limb differences. Beyond the obvious musical potential, these instruments can foster a sense of empowerment and self-expression. The ability to create music, often a highly personal and fulfilling activity, can boost self-esteem and provide a platform for social connection. The customized nature of 3D printing allows for precise adaptation to individual needs and preferences, thus improving comfort and control.

3D-printed prosthetics are becoming more than just replacements; some are being transformed into instruments! Imagine the possibilities, and how this could revolutionize accessibility in music. It’s fascinating how creative applications like this are evolving, and I’m super excited to see how this technology will progress, especially with news about pinballs coming to the playdate pinballs coming to the playdate.

This innovative approach is really pushing the boundaries of what’s possible, especially with 3D printed prosthetics. Maybe soon we’ll see musicians performing with instruments made from custom-fitted prosthetic limbs!

This can lead to improved quality of life and a more active engagement in society.

Challenges and Considerations for Accessibility and Usability

Several challenges need careful consideration when designing accessible and usable 3D-printed prosthetic instruments. Firstly, the instruments must be robust and reliable, ensuring durability and long-term functionality. Furthermore, the materials used must be non-allergenic and comfortable against the skin, preventing irritation or discomfort. The intricate design of the instrument must not compromise the user’s range of motion or ability to perform everyday tasks.

Improving Comfort and Playability of These Instruments

Optimizing comfort and playability requires careful consideration of various factors. Ergonomic design principles are crucial, ensuring that the instrument conforms to the user’s unique anatomy. The weight and balance of the instrument are essential factors for comfortable playing, and the design should minimize stress points and pressure points. Innovative material choices that combine lightness, strength, and tactile responsiveness could enhance playability.

User Feedback on Prosthetic Instruments

Collecting and analyzing user feedback is critical to refining the design and functionality of 3D-printed prosthetic instruments. The table below Artikels a potential structure for gathering this feedback.

| Feature | Positive Feedback | Negative Feedback |

|---|---|---|

| Comfort | Smooth contours, minimal pressure points, lightweight materials | Irritation, discomfort in certain areas, excessive weight |

| Sound | Rich tones, expressive dynamics, clear articulation | Unpleasant or distorted sounds, limited dynamic range, lack of desired timbre |

| Playability | Easy to manipulate, responsive controls, natural feel | Stiff or unresponsive controls, complex techniques, difficult to master |

Applications and Future Potential

D-printed prosthetic instruments, merging the worlds of medical technology and musical artistry, open exciting avenues for education, therapy, and performance. These instruments offer a unique approach to fostering creativity, rehabilitating patients, and enriching musical experiences. Their potential extends beyond simply providing a functional replacement, offering personalized sound and interactive musicality.These prosthetic instruments have the potential to revolutionize how we approach music education, therapy, and performance.

The ability to tailor the instrument’s design and sound to an individual’s specific needs opens up a new realm of musical expression. The focus now shifts to exploring these applications in more detail.

Potential Applications in Education

Personalized learning experiences are at the heart of effective education. 3D-printed prosthetic instruments can be customized to cater to diverse learning styles and needs. Students can explore musical concepts in a hands-on, engaging way. They can adjust the instrument’s design to explore various timbres and techniques, fostering a deeper understanding of sound production.

Potential Applications in Therapy

These instruments can be powerful tools in therapeutic settings. They provide a medium for patients to express themselves creatively, fostering emotional well-being and promoting a sense of accomplishment. The focus on sound and musicality can provide an outlet for patients to cope with challenges and improve their motor skills.

Potential Applications in Performance

The unique sound and design of 3D-printed prosthetic instruments offer a distinct aesthetic in musical performances. Imagine a band incorporating these instruments, creating a captivating blend of familiar and innovative sounds. Their individuality can inspire original compositions and lead to new forms of musical expression. Musicians could even personalize the instrument to fit their individual playing styles.

Examples of Musical Performances

These instruments could be integrated into various musical genres. Imagine a string quartet with a 3D-printed prosthetic cello, or a jazz ensemble featuring a custom-designed trumpet prosthesis. The possibilities are limitless, with each performance offering a unique and captivating musical experience.

Collaborations and Partnerships

Collaborations with musicians, engineers, and medical professionals are crucial for developing these instruments and maximizing their impact. This interdisciplinary approach ensures the instruments are not only aesthetically pleasing but also functionally sound and accessible. The development and refinement of these instruments would benefit significantly from the combined expertise of these fields.

Future Advancements

Ongoing research in biomaterials and 3D printing technology will likely lead to more intricate and expressive instruments. The integration of sensors and actuators could provide even greater levels of customization and control, enhancing the musical experience. This innovation promises to bridge the gap between medical technology and musical performance.

Potential Impacts on the Music Industry

| Area | Potential Impact ||—|—|| Education | Enhanced musical learning experiences, fostering creativity and personalized learning. || Therapy | Improved emotional well-being, increased patient engagement, and enhanced motor skills development. || Performance | Introduction of unique soundscapes, inspiration for new compositions, and the creation of innovative musical forms. |

Final Conclusion

In conclusion, the prospect of 3D printed prosthetics evolving into musical instruments is brimming with potential. This innovative approach not only provides a novel artistic outlet for individuals with limb differences but also opens doors to exciting advancements in sound design and musical expression. The future of music and technology intertwines in remarkable ways, as this fusion of function and artistry promises to redefine both fields.